List of mainstream production processes for lithium hydroxide

Aug,16,24

The main processes currently used to achieve large-scale industrial production of lithium hydroxide worldwide are:

Lithium sulphate causticising method, lithium carbonate causticising method and limestone roasting method.

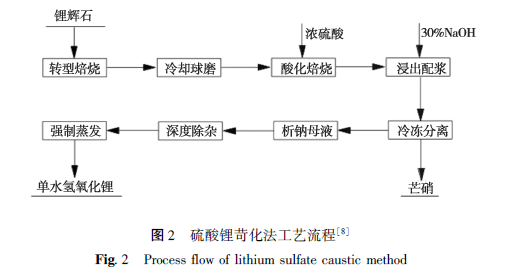

Lithium sulphate causticisation is the most mature process for the production of lithium hydroxide using lithium pyroxene in China.

Lithium sulphate causticising method (ore method):

Under the environment of 950-1100 ℃ for the conversion of lithium concentrate roasting

and 250-300 ℃ in the environment of the acidification of the roasting,

neutralisation and leaching to get lithium sulfate leach solution and forced evaporation,

and then based on the lithium content of the leach mother liquor to add caustic soda solution,

in the case of freezing to -10 ℃ precipitation of nitrous oxide,

and finally the depth of the removal of impurities and once again forced evaporation of monohydrate lithium hydroxide.

This method uses physical freezing to achieve the separation of manganese nitrate and lithium hydroxide,

which is a short and mature process with high comprehensive benefits,

but it also has the problems of high energy consumption and difficult to achieve superior product quality.

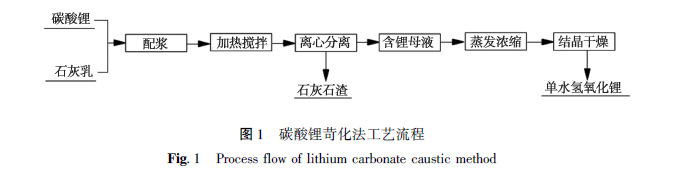

Lithium carbonate causticising method (causticising method):

This method requires mixing lithium carbonate with refined lime milk at a molar ratio of 1:1.08

and adjusting the concentration of the causticised solution to 18-20 g/L, after which it is heated to boiling and strongly stirred.

After centrifugal separation to get CaCO3 precipitation and lithium hydroxide mother liquor,

and finally evaporation and concentration of the mother liquor and crystallisation and drying to get monohydrate lithium hydroxide.

Lithium carbonate causticisation is a mature process, with a short production process, lower energy consumption and smaller requirements for material flow,

but it requires higher purity raw materials and has the problems of relatively complicated decontamination process and low recovery rate.