Innovation in Energy Storage Battery Technology: "6+1" Battery Cell Material System

Jul,31,24

1、 Introduction

In the context of the global energy structure transformation,

the development and innovation of energy storage battery technology, as a key bridge connecting renewable energy and traditional power grids, are crucial.

With the rapid rise of the electric vehicle market and the widespread application of renewable energy,

the performance requirements for energy storage batteries are also increasing.

Especially in terms of thermal runaway, energy density, charging speed, and safety, existing energy storage battery technologies are no longer able to meet market demand.

Therefore, innovating energy storage battery technology has become an inevitable trend in the development of the industry.

In high-power and high-capacity energy storage systems, batteries generate a large amount of heat during discharge. If these heat cannot be dissipated quickly and evenly,

it may lead to excessive temperature differences between battery packs, thereby affecting the lifespan and safety of the batteries.

Although the traditional bottom liquid cooling heat dissipation method has a simple structure,

it cannot effectively cool the battery parts far away from the liquid cooling plate, resulting in local high-temperature areas inside the battery.

2、 Technical Background and Application

At present, while a large number of breakthrough new technologies that improve product performance and efficiency are being applied,

industry bottlenecks and safety crises are becoming increasingly prominent, especially the thermal runaway problem of lithium-ion batteries.

Traditionally, solving battery thermal problems in the industry has mainly been achieved by optimizing the external system of the battery cells,

but the effect is limited. Therefore, Changnengda decided to start with the internal material system and carry out technological innovation.

Changnengda Technology has proposed a "6+1" battery cell material system based on phase change ultra-thin heat dissipation plates to solve the thermal management problems of energy storage batteries.

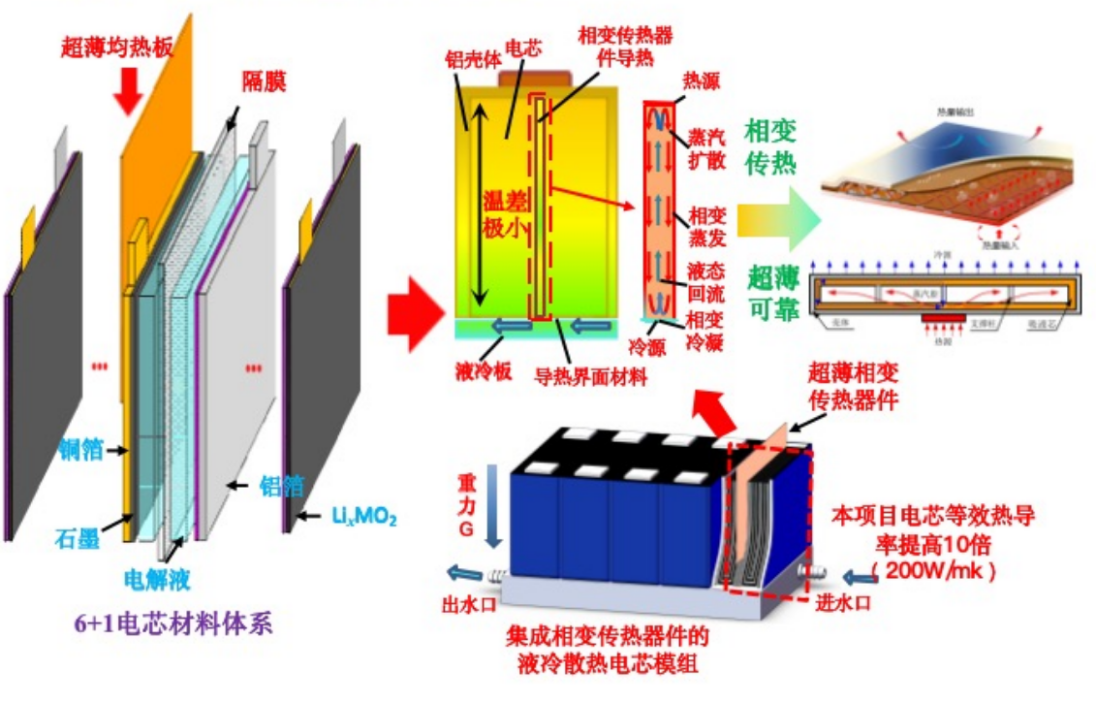

The "6+1" new battery material system is based on the old material system of "copper foil graphite separator electrolyte aluminum foil LixMO2",

with the addition of ultra-thin heat dissipation plates with a thermal conductivity of ≥ 10000W/mK, significantly improving the equivalent thermal conductivity of the battery.

During the charging and discharging process of energy storage lithium batteries, the internal temperature should be higher than the external temperature, and the larger the current,

the greater the temperature difference between the inside and outside of the battery cell;

The liquid cooled hot water cooling plate for energy storage batteries is usually arranged at the bottom,

and the heat dissipation effect at the bottom of the battery is significantly better than that at the top,

resulting in a large temperature difference in the vertical direction of the battery.

In the "6+1" new battery material system,

we build a high thermal conductivity channel inside the battery cell through ultra-thin heat sharing plate devices to improve the overall equivalent thermal conductivity of the battery cell,

efficiently transfer heat to the bottom liquid cooling for heat dissipation, reduce the maximum temperature of the battery cell,

the temperature difference between the inside and outside, and the vertical temperature difference,

so as to control the temperature of the battery in the optimal temperature range and improve the life of the energy storage battery.

In addition, reverse heating is used in low-temperature (minus zero) environments to quickly raise the temperature of the battery to the usable temperature range,

in order to solve the problem of battery charging and discharging.

By using our developed ultra-thin heat dissipation plate device to build a high thermal conductivity channel, we not only achieve efficient heat dissipation of energy storage batteries,

but also achieve efficient preheating of energy storage batteries, thereby preventing and suppressing battery thermal runaway.

3、Introduction to the 3 "6+1" Battery Cell Material System

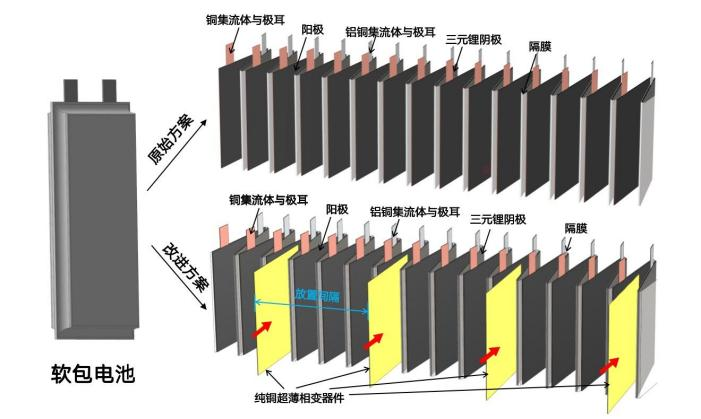

To address this issue, Changnengda Technology has proposed an innovative "6+1" battery cell material system.

The traditional lithium-ion battery material system includes the following parts: copper foil, aluminum foil, anode material, cathode material, separator, and electrolyte.

Although this combination method achieved good application results in the early stages,

there are still some bottlenecks when facing large-sized energy storage cells and high rate charging and discharging.

Changnengda's "6+1" battery cell material system is based on traditional battery materials, with the addition of an ultra-thin heat dissipation plate.

Its thermal conductivity exceeds 10000W/mK, significantly improving the equivalent thermal conductivity of the battery.

This ultra-thin uniform heating plate establishes a high thermal conductivity channel inside the battery cell,

effectively transferring heat to the bottom liquid cooling plate and achieving rapid dissipation of heat.

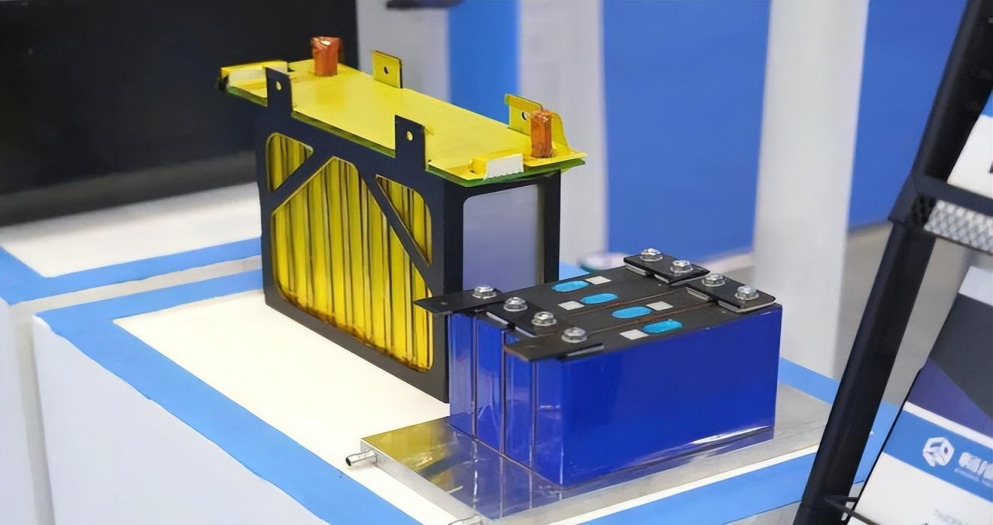

Figure 1 "6+1" Battery Cell Material System

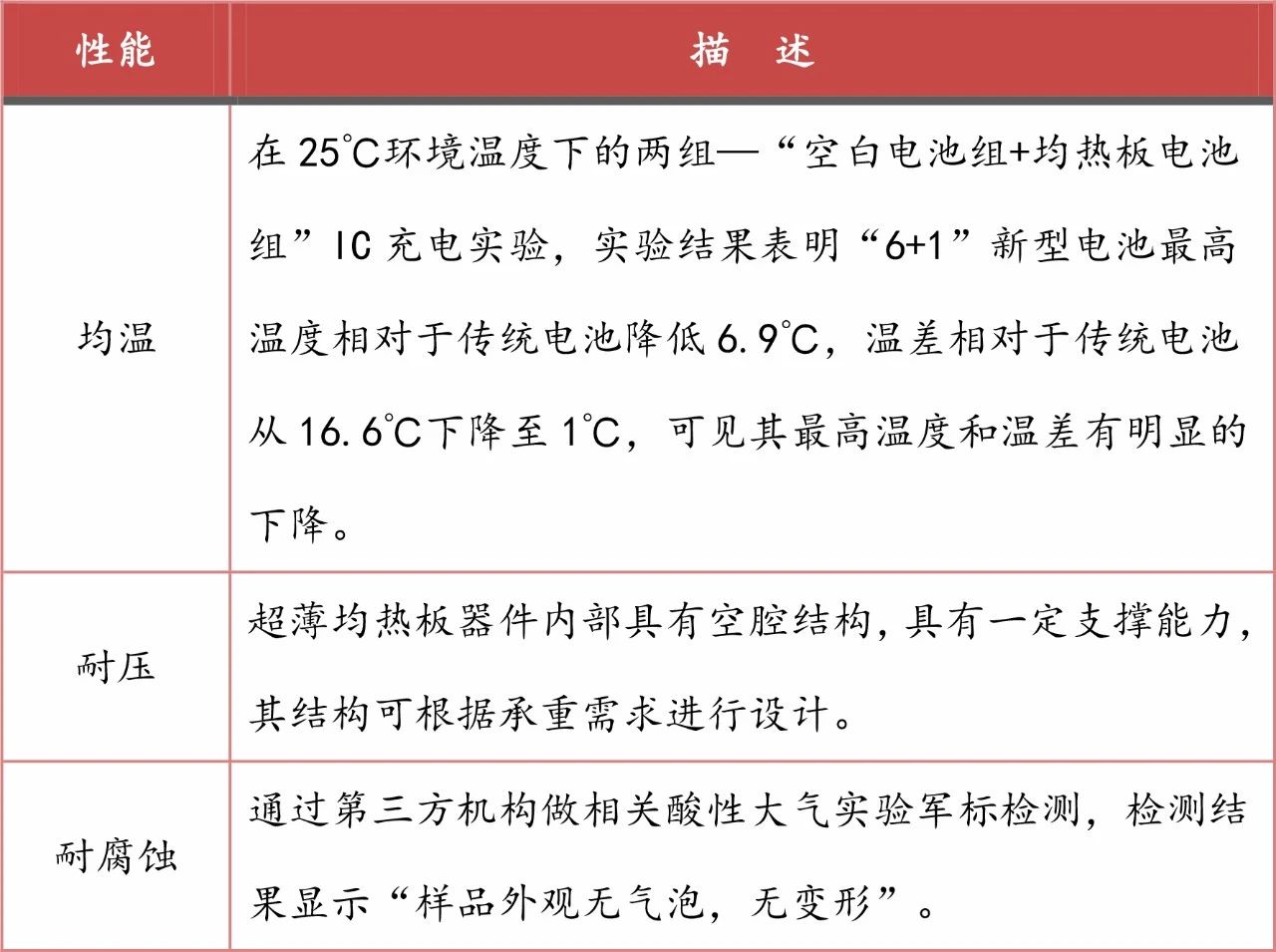

The working environment of ultra-thin uniform heat plate devices in the "6+1" new battery material system is special,

requiring the devices to have corrosion resistance, pressure resistance and other properties, as shown in Table 1.

Table 1 Performance Description

4、Advantages of the "6+1" battery cell material system

1. High thermal conductivity:

The introduction of phase change heat transfer materials significantly improves the thermal conductivity of the entire battery cell,

solving the thermal management problem of traditional battery cells during high rate charging and discharging.

2. Lightweight design: By optimizing materials and processes, ultra-thin and lightweight battery cells have been achieved,

which not only increases energy density but also reduces manufacturing costs.

3. Flexible design: The new VC heat dissipation plate supports a heat dissipation power of 30W and can achieve 90 ° bending,

supporting flexible design, which provides more possibilities for battery application scenarios.

4. Safety improvement: By optimizing the internal structure of the battery cell and introducing new materials,

the risk of thermal runaway has been significantly reduced, thereby improving the safety of the battery.

5 Application Prospects and Market Potential

The successful research and development of the "6+1" battery material system marks Changneng Da's leading position in the field of lithium-ion batteries.

The thermal management technology of energy storage batteries based on ultra-thin heat sharing plates enables battery modules to achieve rapid heat dissipation even in high-power working environments;

The temperature difference inside the battery is controlled within 5 ℃ to extend its service life and improve safety.

As shown in Figure 2, the ultra-thin heat distribution plate is designed in an I-shape according to the requirements.

The ultra-thin heat distribution plate has high thermal conductivity and can efficiently transfer heat to achieve heat dissipation,

effectively reducing the maximum temperature of the battery cell and the vertical temperature difference, reducing heat concentration,

and controlling the temperature of the battery in the optimal temperature range, thereby improving battery life.

Figure 2 Thermal management scheme for energy storage batteries based on ultra-thin heat sharing plates

This system is not only applicable to the energy storage field,

but can also be widely used in multiple fields such as electric vehicles and portable electronic devices.

With the continuous growth of global demand for new energy and energy storage, the "6+1" system is expected to become mainstream in the market in the next few years,

bringing huge economic and social benefits.

Through these innovative technologies, Changnengda Technology's "6+1" battery material system not only improves the performance of energy storage batteries,

but also ensures their safety and stability, providing strong technical support for the development of the energy storage market.