New technology for power batteries: Lithium metal negative electrode can replace solid-state batteries as the new favorite in the market

Aug,07,24

In recent years, solid-state batteries have undoubtedly been the focus of car companies' pursuit, while lithium-ion batteries,

known as the "ubiquitous energy revolution", are also widely used in the field of new energy vehicles.

However, the energy density limit of graphite/silicon anodes restricts the development of lithium battery technology,

making it difficult to meet the urgent market demand for higher energy density and longer endurance.

Lithium metal negative electrodes are known as the "holy grail" of the next generation of lithium negative electrode materials

due to their excellent energy density and extremely low reduction potential,

carrying the mission of breaking through the performance limits of lithium batteries.

At present, EVE Energy's lithium metal negative electrode batteries have reached 450Wh/Kg, with a cycle life of over 800 times.

Domestic and foreign battery companies such as CATL,

Tianqi Lithium, Tailan New Energy, Xinwangda, LG, Anhui Mengwei, SK New Energy,

as well as domestic and foreign car companies such as Geely, SAIC, General Motors, and Honda, are actively laying out their plans, with broad prospects for the future.

However, lithium metal anodes also face multiple challenges such as drastic volume changes, lithium dendrite growth, and side reactions caused by high activity.

Researchers both domestically and internationally are exploring various solutions to address this issue. We would like to share with you some of our latest research findings!

1. Accurate regulation of SEI film

Top domestic research teams such as the Institute of Metal Research at the Chinese Academy of Sciences have successfully constructed a more stable

and uniform SEI film by finely regulating the composition of the electrolyte and adding specific additives,

significantly improving the safety and cycling stability of lithium metal batteries.

In addition, the Robert Kostecki team at Lawrence Berkeley Laboratory in the United States has also made significant breakthroughs in the field of SEI film research.

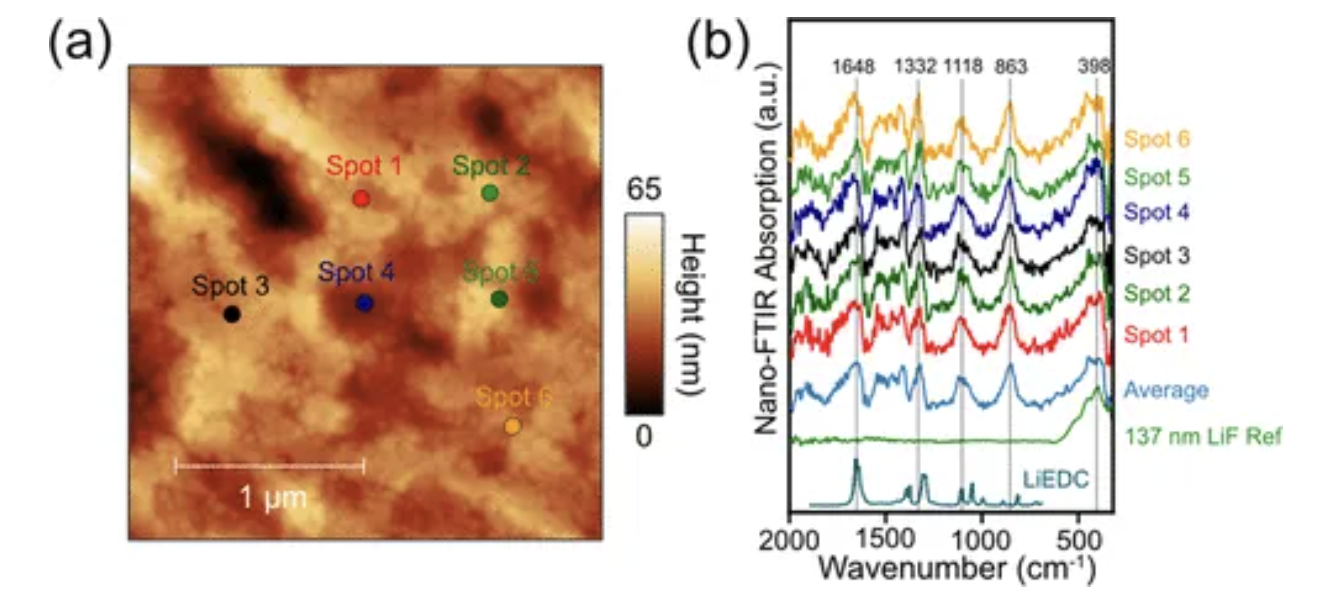

AFM image and SIBNS absorption spectrum of 50 nm thin film amorphous silicon electrode

They deeply analyzed the chemical composition, nanoscale structure, and formation process of SEI film,

and found that through carefully designed electrolyte formula and additive combination,

the formation path of SEI film can be precisely controlled, promoting its development towards a more uniform, dense, and stable direction.

This innovation not only significantly improves the energy density and cycle life of batteries,

but also effectively extends the overall service life of batteries, laying a solid foundation for the widespread application of lithium-ion batteries.

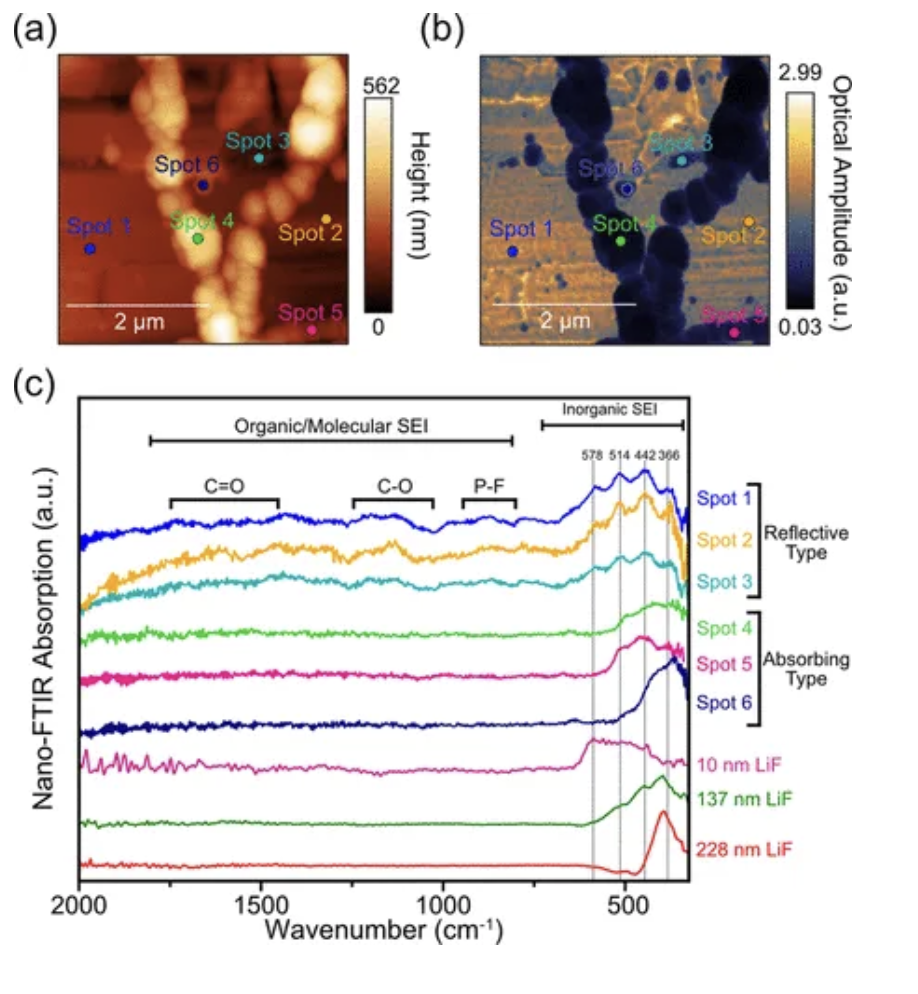

AFM image, infrared white light image, and SINS absorption spectrum of Si40Al50Fe10 electrode after one formation cycle at C/25

What is particularly noteworthy is that the Kostecki team has also introduced cutting-edge synchrotron radiation infrared nanospectral (SINS) technology,

achieving precise nanoscale characterization of key components (such as LiF) in SEI films.

The application of this technology enables them to clearly observe subtle changes in the internal structure of the SEI film,

providing unprecedented data support and scientific basis for precise regulation of the SEI film.

2. Innovative Design of Lithium Composite Structures

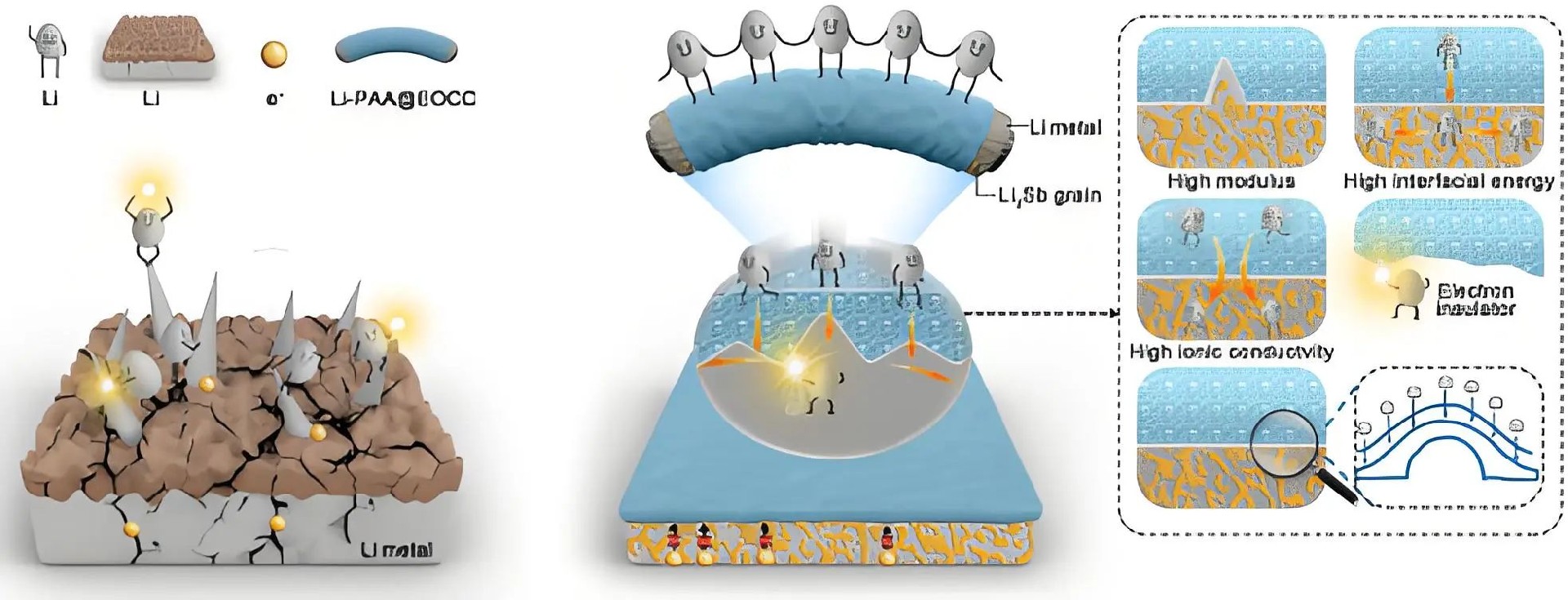

Recently, Professor Zhang Yun's team from the School of Materials Science and Engineering

at Sichuan University ingeniously utilized poly (antimonic acid) (PAA) material and successfully developed

an integrated composite lithium metal negative electrode with a top-down component gradient through a unique reaction with metallic lithium.

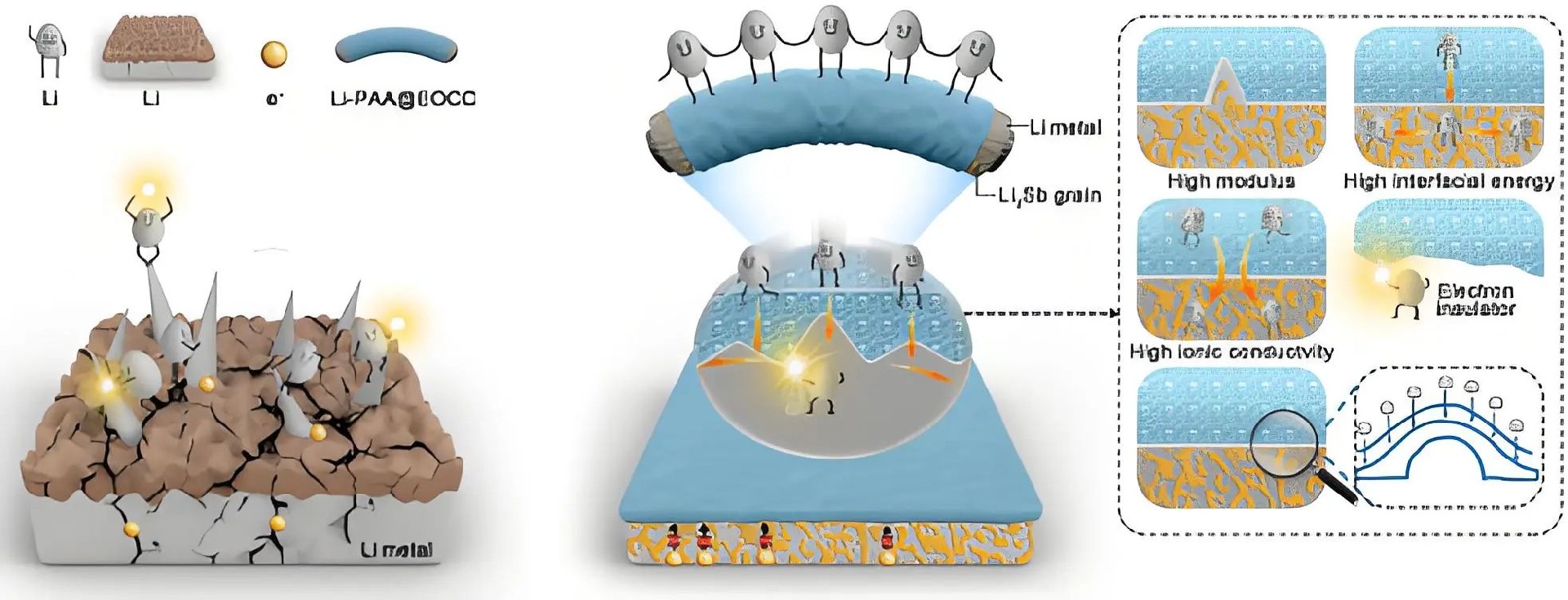

Integrated composite lithium metal negative electrode effectively inhibits dendrite growth

This design not only significantly enhances the electrochemical stability of the negative electrode,

but also effectively suppresses the lithium dendrite growth problem that has long plagued lithium metal batteries.

PAA rich in lattice water reacts with lithium under thermal induction to form a composite negative electrode consisting of multiple layers such as Li2O, LiOH, and Li3Sb.

The robust Li2O rich layer serves as a protective layer, effectively blocking the occurrence of side reactions,

while the LiOH-Li3Sb intermediate layer promotes rapid and uniform transport of lithium ions, ensuring dendrite free deposition of lithium metal.

Process diagram for preparing three-dimensional skeleton with gradient dielectric properties

The research team also designed a three-dimensional skeleton structure with reverse gradient dielectric properties to address

the issue of low lithium ion transport efficiency on three-dimensional substrates.

This structure optimizes the lithium ion transport path to achieve uniform deposition of lithium ions from bottom to top, effectively preventing dendrite formation.

At the same time, the Li3Sb layer formed during deposition enhances the lithium affinity of the three-dimensional structure, reduces the lithium nucleation energy barrier,

promotes the smooth deposition of lithium metal, and provides a new solution for constructing efficient and stable lithium metal negative electrodes.

LG Chem、 International giants such as Samsung SDI have actively intervened, striving to apply it to practical products, improve battery performance, and meet market demand.

3. Development and Application of Solid Electrolytes

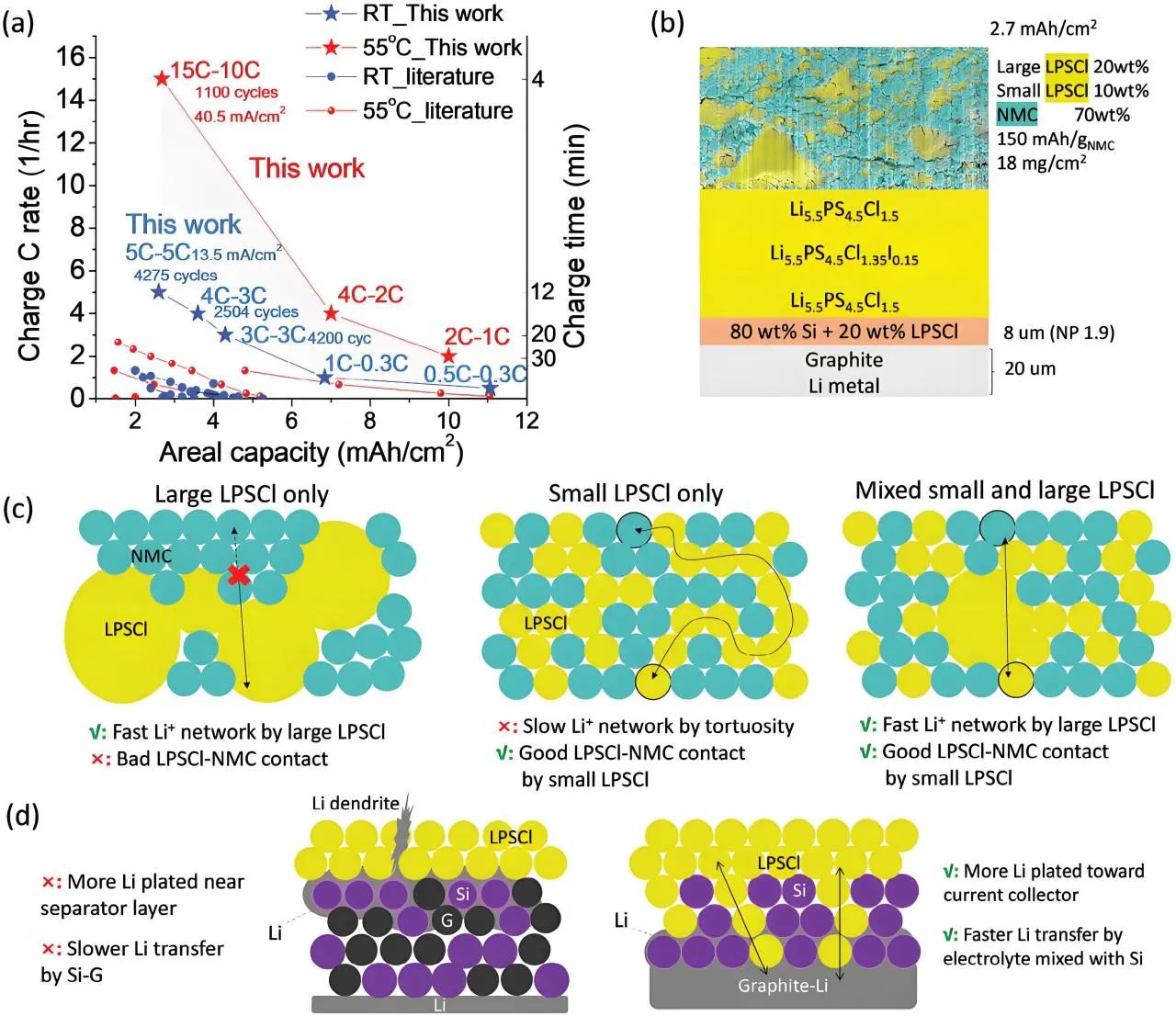

Professor Xin Li's team at Harvard University has successfully developed a new generation of solid-state battery technology,

which achieves high-speed charging and discharging capabilities with high surface capacity (>2 mAh cm - ²) through precise hierarchical design of positive

and negative electrode composite materials.

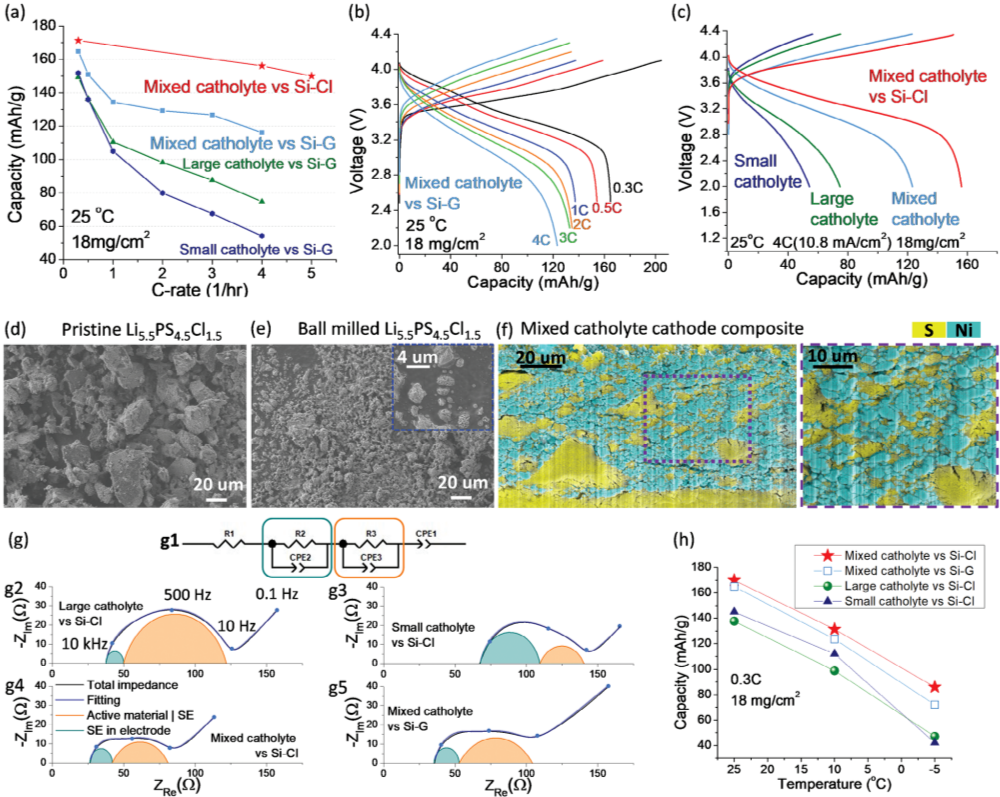

Battery performance and full battery design

This technology adopts a mixed strategy of large and small particle electrolytes in the positive electrode,

effectively reducing the transmission impedance and interface impedance of lithium ions inside the electrode,

ensuring that lithium ions can quickly pass through the thick electrode with low tortuosity and fully contact with the active material NMC.

In terms of negative electrode, the team innovatively improved the structure of silicon carbon | lithium metal composite,

significantly enhancing the uniform distribution and rapid transmission efficiency of lithium ions by mixing micro silicon with LPSCl electrolyte.

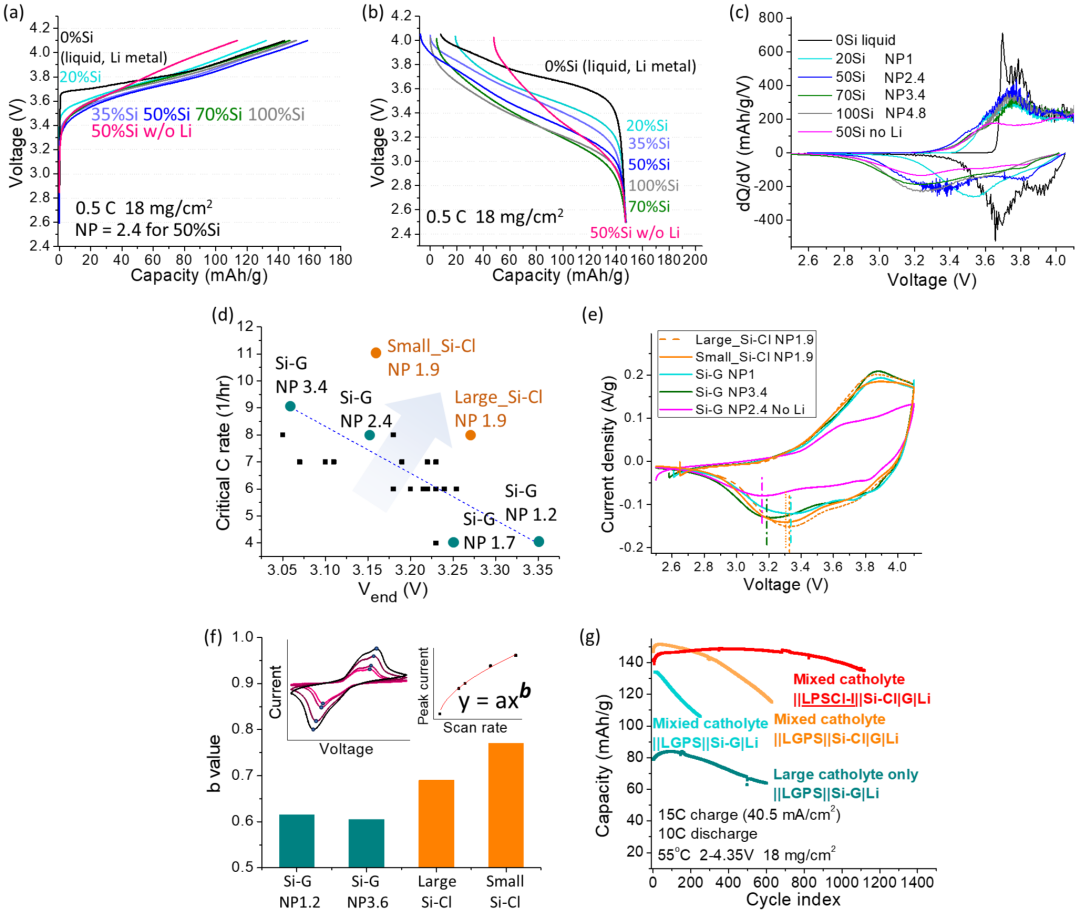

Comparison of electrochemical characterization using different positive and negative electrode structures

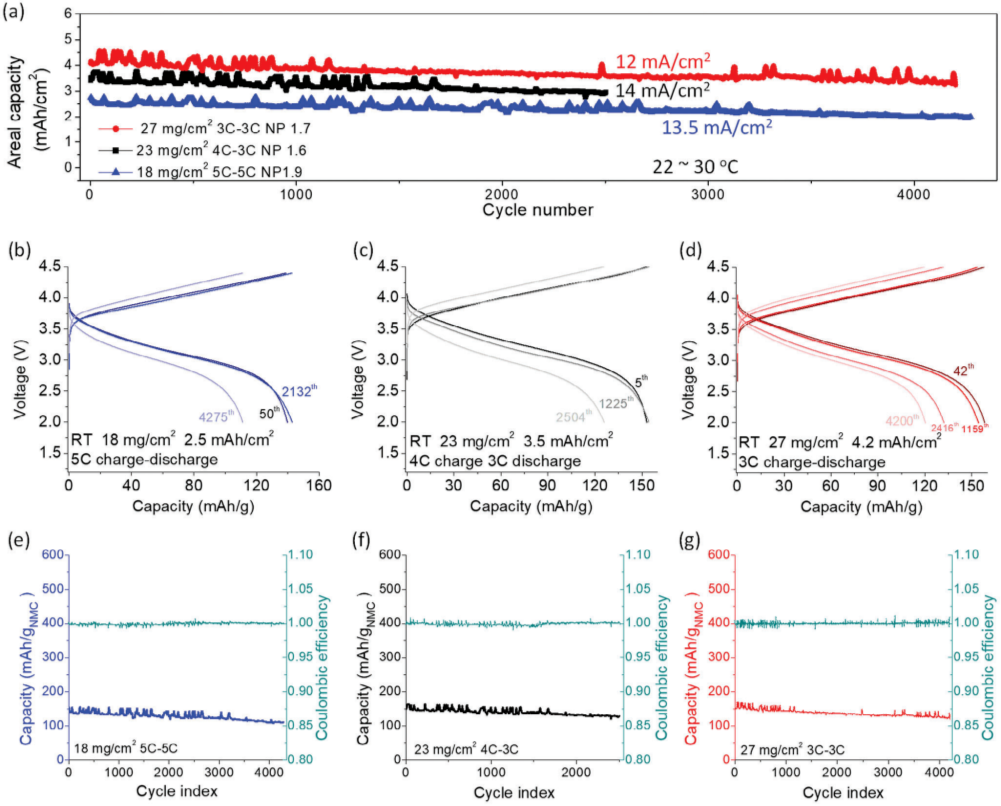

This technology breaks the traditional negative correlation relationship,

achieving stable cycling of over 4000 cycles at 5C rate at room temperature and 1100 cycles of 15C charging and 10C discharging at high temperature,

significantly improving the performance and adaptability of solid-state batteries.

Emerging solid-state battery companies such as Solid Energy and QuantumScape are committed to commercializing solid-state electrolyte technology.

They are collaborating with automotive manufacturers such as BMW and Ford to promote the mass production and application of solid-state batteries.

Full battery cycling performance

Negative electrode electrochemical analysis

At present, several companies have made significant breakthroughs in lithium metal anodes.

LG New Energy, an old rival of CATL, has ambitiously set a goal to launch lithium metal batteries with a volumetric energy density of about 1000Wh/L by 2028.

This breakthrough aims to solve the endurance problem of high-energy demand applications such as electric vehicles and robots.

LG New Energy is committed to improving the reversibility of lithium metal anodes, thereby extending the durability

and cycle life of batteries and bringing unprecedented power solutions to the market.