New understanding - the morphological evolution behavior of lithium in lithium metal batteries

Aug,13,24

In recent years, lithium metal batteries have become a research hotspot again as the batteries with the highest theoretical energy density.

However, the proliferation of dendrites and accumulation of dead lithium in lithium negative electrodes seriously hinder the practical application of lithium metal batteries.

Clarifying the mechanism of dendrite formation in lithium negative electrodes under different conditions is the key to solving the negative electrode problem.

According to the currently recognized diffusion control model, lithium negative electrodes will not produce dendrites below the limit current density.

However, a large number of research results have shown that dendrites will still form in lithium negative electrodes below the limit current density,

leading to premature failure of the battery.

The mechanism of dendrite formation under safe conditions (below the limit current density) has been a research gap.

[Job Introduction]

Recently, Professor Yuan Wei's team from South China University of Technology focused on the important role played by

the morphological evolution of lithium deposits in the formation of dendrites at negative electrodes below the limit current density/capacity,

and proposed a new insight into the growth behavior of lithium.

At the same time, based on the understanding of morphological evolution,

a negative electrode surface morphology design was proposed that can eliminate the compression of lithium deposits

at the interface and achieve effective contact between the electrolyte and the negative electrode active surface.

This negative electrode morphology is achieved through a simple and low-cost mechanical processing method, namely the imprinting method.

The new understanding of negative electrode growth behavior

and the new methods for inhibiting dendrites proposed in this article can provide

new concepts and strategies for promoting the development of practical lithium metal negative electrodes.

This work has been published in the top international journal ADVANCED INTERNATIONAL SYSTEMS. Wang Chun is the first author of this article.

[Content Description]

1. Analysis of the morphological evolution of lithium deposits and the mechanism of dendrite formation under low current density

This article analyzes in detail the morphological evolution of lithium deposits on the interface of flat and embossed surfaces of lithium negative electrodes

by disassembling and characterizing high-definition SEM images of lithium metal batteries after different cycles.

For planar lithium negative electrodes, after uneven nucleation and deposition of lithium on the surface of the negative electrode substrate,

large dendritic structures quickly appear on the surface of the planar electrode.

Afterwards, adjacent growing dendrites squeezed each other and the membrane, resulting in a shielding zone at the bottom that could not participate in the reaction.

As the cycle progresses, a large amount of dead lithium and pitting corrosion also occur, and ultimately the negative electrode completely fails after multiple cycles.

The curved lithium electrode, due to the presence of electrolyte storage areas, enables lithium to nucleate and deposit more uniformly,

while avoiding compression between lithium deposits and the separator, forming an approximately ideal film deposition.

Figure 1. Evolution of interface morphology of planar and embossed surfaces of lithium negative electrode after different cycles

2. The influence of squeezing and electrolyte contact on the stable cycling of negative electrode

This article characterizes the planar and curved lithium negative electrodes after long cycles using SEM.

As the number of cycles increases, an increasingly thick dead lithium layer forms at the top of the planar lithium electrode.

The dead lithium layer is composed of various forms of dead lithium,

including sharp dendritic branches that are easily punctured by membranes and irregularly shaped lithium blocks.

After 100 cycles, its thickness is about 240 μ m.

Due to the significant volume change of dendritic lithium and the increasing pressure between the positive

and negative electrodes provided by the gradually thickening dead lithium layer,

each deposition/stripping process is like compressing the dead lithium layer again and again,

which makes the dead lithium layer denser and the ion transport channel longer and more tortuous.

In addition, cracks appeared on the upper surface of the dead lithium layer,

which were caused by the pressure brought by the increase in the thickness of the dead lithium layer

and the stress brought by the compression of dendritic lithium.

At the contact point between the dead lithium layer and the negative electrode, extensive cracking caused by shielding areas and pits can be observed.

The morphology of the planar lithium electrode after long cycles also supports our understanding of

the failure mechanism of lithium negative electrodes at low current densities.

Due to sufficient electrolyte contact and low local current density, the valley of the curved lithium electrode gradually fills with increasing cycling.

The valley was filled after about 200 cycles.

The filling of the valley floor is more in line with the Sand'time theory, and most of the lithium sediments exist in a mossy form.

The stable morphology of the curved lithium negative electrode after long cycles confirms

the importance of no compression and sufficient electrolyte contact for stable cycling.

Figure 2. Surface morphology of planar and curved lithium negative electrodes after long cycles

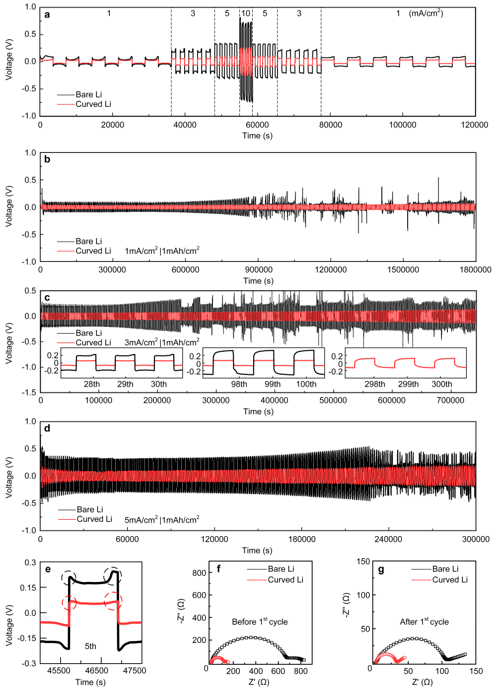

3. Performance of embossed curved lithium negative electrode battery

The embossed curved negative electrode achieves uniform lithium deposition/stripping without dendrite formation.

Compared with symmetrical batteries using flat lithium anodes, symmetrical batteries using curved lithium

anodes exhibit lower overpotentials at current densities ranging from 1C to 10C.

This is attributed to the three-dimensional undulating surface of the curved lithium negative electrode,

which provides a larger active surface area within the same geometric dimensions.

When the same magnitude of current is applied, the charge transfer resistance

and interface polarization at the curved lithium negative electrode interface are smaller.

A symmetrical battery using a curved lithium negative electrode

can stably cycle over 300 times under the condition of 3mA/cm2 | 1mAh/cm2.

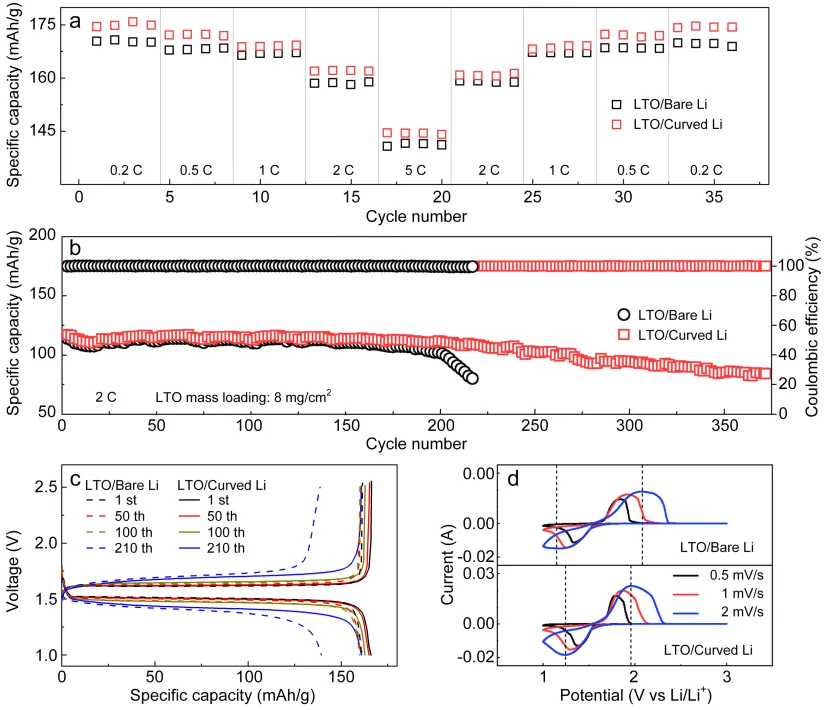

In the testing of the entire battery, the curved lithium negative electrode matched

with LTO positive electrode assembly showed smaller polarization and better cycling stability,

mainly due to the stable cycling of the curved lithium negative electrode without dendrites.

The entire battery was able to cycle stably for more than 350 times at 2C.

Figure 3. Full battery performance using curved lithium anode

Figure 4. Full battery performance using curved lithium anode

【 Conclusion 】

This article proposes the failure mechanism of lithium metal negative electrode at low current density.

Taking into account the narrow and limited space between the positive and negative electrodes of actual batteries,

an analysis was conducted on longer cycle periods from the beginning of the cycle,

pointing out the significant impact of lithium deposition compression

and the resulting electrolyte deficiency on the deterioration of the negative electrode interface.

Based on this mechanism, we propose a new strategy - using mechanical imprinting method to manufacture curved lithium metal electrodes.

The grooves on the surface of the curved lithium sheet provide a relaxation space for lithium deposits that is not compressed and can effectively store electrolyte.

By combining the expanded electroactive area of the 3D surface of the curved lithium negative electrode

with the effective maintenance of the electroactive area caused by the absence of dendrites,

lithium metal batteries using curved lithium negative electrodes have achieved outstanding performance improvements.

This article introduces the "old method, new application" of the traditional mechanical process of imprinting,

which has brought astonishing performance improvements by simply constructing a simple curved surface on the surface of lithium sheets through mechanical deformation.

This means that constructing relaxation spaces on the negative electrode surface

is an effective means of suppressing dendrites and improving the cycle life of lithium metal batteries.

Further optimization of the negative electrode interface based on the ideas provided in this study is expected to promote the practical application of lithium metal batteries.