Dimethyl Disulphide( DMDS ) 99.60%

PRODUCT FEATURES

1)Oil Refining: Optimal Maintenance Of Production Units. DMDS Is Used In Oil Refineries As A Sulfiding / Presulfiding Agent To Activate The Catalysts Of Hydrotreating Units. This Is An Indispensable But Delicate Operation. An On-Site Sulfiding Service Carried Out By Highly Qualified Technicians. Has Also Developed An Improved, Lower Odor Version Of DMDS Called DMDS Evolution.

2)Petrochemicals: To Reduce The Number Of Decoking Operations. Operators In The Petrochemicals Industry Must Protect Their Steamcracking Coils Against The Formation Of Coke And Carbon Monoxide. DMDS Is The Ideal Sulfurous Product For Them. DMDS Can Be Added Continuously To The Raw Materials To Maintain An Optimal Sulfur Level, Making It Possible To Reduce The Number Of Decoking Operations. The Secondary Reactions To These Operations Are Easier To Control And The Production Cycles Are Lengthened.

3)Fine Chemicals, As Chemical Intermediate

4)Metallurgy For Its Anti-Corrosion Properties.

Product Name : Dimethyl Disulfide ( DMDS), 2,3-Dithiabutane.99.60% Min

Product Description:

Molecular Weight: | 94.0 | Cas Number : | 624-92-0 | |

Chemical Formula: | (C2H6S2) | |||

Physical/ Organoleptic Characteristics: | Appearance : | Colorless Or Light Yellow Liquid , | ||

Purity : | 99.60 Pct. Min. , | |||

Chemical Characteristics:

| Density ( 20/4 Deg. C) : | 1.062 ± 0.02 | ||

Sulphur Content: | 68.1 Ptc. Min. | |||

Water Content : | 0 - 0.06 Ptc . Max ., | |||

Flash Point(Cc): | 16 Deg. C. Min | |||

Boiling Point : | ( 108 Deg. C-110 Deg. C) | |||

Refractive Index: | 1.526 ±0.02 ( 20 Deg C ) , 1.508 ± 0.02 ( 30 Deg.C ) | |||

Incandesce Reside : | 0 --- 0.1 Pct | |||

Total Nitrogen: | 0 - 100 Ppm | |||

Solubility : | Insoluble In Water , Soluble In Alcohol And Ether . | |||

Methyl Mercaptan Content: | 0.001%--0.05% | |||

Non Volatile Residue.: | 0.03% Max | |||

Freezing Point: | - 121 F( - 85 Deg C ) | |||

Viscosity At 25 C -Cp : | 0.8cp | |||

Vapor Pressure @ 25 C -Mm : | 28.6 Mmhg | |||

Molecular Wt. : | 94.20 | |||

Surface Tension At 20 C - Dynes/Cm.: | 1.06cm | |||

Microbiological Characteristics: | Not Specified. | |||

Packaging: | 1) In Bulk ( 20 FT ISO - Tank Container). 2) In 240 Kg Net Weight New Iron Drum .. 3) In 200 Kgs Net Weight New Iron Drum. | |||

Storage Conditions: | Store In Dry Conditions, Free From Infestation, In Tightly Closed Containers. | |||

Approved Suppliers &Exporter: | Xiamen J&Y Import And Export Co., Ltd | |||

Shelf Life: | 36 Months. | |||

Packing :

1. Packed In 20 Ft Stainless Steel Iso- Tank ,It Is 24cbm. And Put Total 21mt +/- 5% Max In One 20 Ft Iso Tank Container In Bulk . Iso Tank ‘S Size : 6058mm X 2438mmx 2591mm .Iso –Tank Made In French And Uk. Germany .Quality Certificated By Abs . Bv. Lloyd.With 500mm Manhole On Top .

2. Packed In 240 Kg. New Iron Drum And Firmly Strapped. Non-Returnable New Steel Drums To Withstand Hydrostatic Test Pressure Of 40 Psig For 5 Minutes. Total 19.20mt In One 20 Ft Container .

3. Packed In 200 Kg. New Iron Drum And Firmly Strapped. Non-Returnable New Steel Drums To Withstand Hydrostatic Test Pressure Of 40 Psig For 5 Minutes.. Total 16 Mt In One 20 Ft Container .

ISO Tank Delivery & Shipment :

* Lessee Will Return Equipment To The CLPC. Which Have Been Agreed To In Writing By The Parties.

* Free Discharge Date Is 14 Days At Destination Port,

* Lease Cost: Usd 25/ Per Day -Per Container After Free Discharge Date At Destination Port Until Redelivery ISO

Tank Date At China Port .

* Shipment Date : About 25 Days – 45 Days From Tianjin Port China.

* Maximum Delivery To Replenish Maximum Stock Quantity : 100 Mt

* The Cost Of Repairs Of Iso Tank Will Be Paid By Lessee.

-

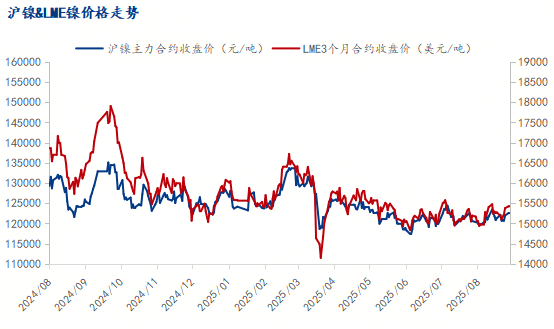

Nickel Market Update - October 28th

Oct,29,2025

-

Market Update on Nickel Prices in Nov.2025

Oct,29,2025

-

Oct,29,2025

-

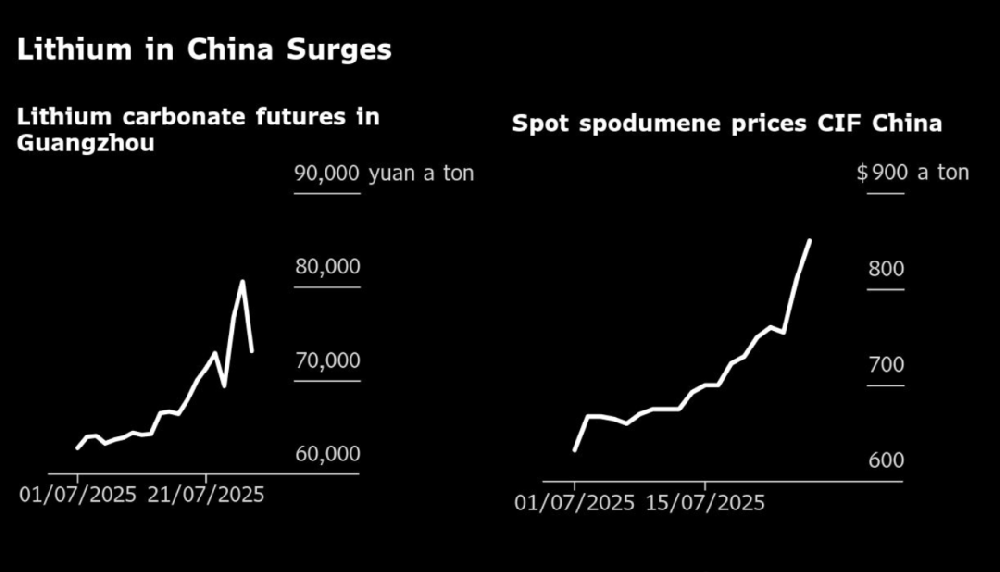

Mid week analysis of cobalt lithium new energy market and prices in October 2025

Oct,29,2025