Research on Lithium Manganese Iron Phosphate Materials

Aug,05,24

The new energy industry is flourishing with the support of national policies, and the sales penetration rate of new energy vehicles is constantly increasing.

Lithium batteries not only provide solutions for the electrification of the next generation of vehicles,

but also become a large-scale energy storage solution for wind and solar power plants, belonging to a high prosperity industry.

As the next generation of lithium iron phosphate material,

manganese iron phosphate lithium improves the cost-effectiveness of lithium batteries and helps the development of the lithium battery industry;

The lithium battery recycling business can solve the risk of environmental pollution caused by waste batteries, and reuse waste lithium battery resources,

which is in line with the concept of national green circular economy.

The market prospect of lithium manganese iron phosphate is promising, and a preliminary consensus has been formed in the industry.

With the rise of lithium iron phosphate, the market volume is about to increase.

As a new generation of iron lithium materials, lithium manganese iron phosphate has better energy density and low-temperature performance than LFP,

and its high temperature, safety, and cost inherit the characteristics of LFP, which is superior to ternary cathodes.

The technology driven market prospect is good, which is an industry consensus.

Giants in the industry have stepped down one after another, whether it is power battery companies, upstream material suppliers, or vehicle manufacturers,

they have all entered the field of lithium manganese iron phosphate batteries.

1. Industry Overview

1. Lithium manganese iron phosphate

The positive electrode material is an important constraint for improving the energy density of LFP batteries.

Increasing the average operating voltage or improving the mass (volume) specific capacity of materials can both enhance the energy density of batteries.

At present, the discharge capacity of mass-produced negative electrode materials has basically reached over 350mAh/g, and silicon-based negative electrodes can reach over 500mAh/g.

However, the actual discharge capacity of lithium iron phosphate positive electrode (LiFePO4/LFP) is 160-170mAh/g,

which is lower than the capacity of negative electrode materials and has approached the theoretical discharge capacity limit.

Therefore, optimizing lithium iron phosphate positive electrode materials has become an important research direction.

The ideal positive electrode material should have the following characteristics:

(1) The discharge platform is high and stable, and does not react with the electrolyte.

(2) The crystal structure is stable, and the change in redox potential during charging and discharging is small,

in order to achieve good cycling performance and a smooth discharge platform.

(3) A higher lithium ion diffusion coefficient can reduce polarization, minimize energy loss, and achieve faster charging and discharging.

(4) There is a large Gibbs free energy in lithium-ion reactions to reduce energy loss caused by polarization.

Lithium manganese iron phosphate (LMFP) is a product of the combination of lithium manganese phosphate and lithium iron phosphate.

By fully combining the advantages of both, its energy density and low-temperature performance are superior to LFP,

while its high-temperature performance, safety, and cost inherit the characteristics of LFP and are superior to ternary.

(1) Lithium iron phosphate and lithium manganese phosphate both belong to polyanionic salts, and their olivine structure gives them both high safety and poor conductivity

(2) Lithium iron phosphate is easy to synthesize, has low cost, and relatively high conductivity, making it relatively successful in commercialization;

However, lithium manganese phosphate has extremely low conductivity and poor stability, and has not been applied yet.

However, the addition of manganese element increases the voltage platform, thereby improving the energy density by up to 21%, which is the shortcoming of lithium iron phosphate.

(3) Due to the similar radii of iron and manganese ions, they can be mixed at the atomic level to obtain lithium manganese iron phosphate that combines the advantages of both.

Lithium manganese iron phosphate has an olivine structure similar to lithium iron phosphate, with good structural stability, high safety, and significant advantages in cost compared to ternary materials.

Image: Performance characteristics of lithium manganese iron phosphate, source: Shanghai Securities Research Institute

However, after adding manganese, the crystal structure undergoes distortion, affecting the cycling and rate performance. Lithium manganese iron phosphate has weaknesses:

(1) Low conductivity, low lithium ion diffusion rate, and poor rate performance.

The electronic conductivity of lithium manganese iron phosphate is more than 10000 times lower than that of lithium iron phosphate,

and the lithium ion conductivity is 1/10 of that of lithium iron phosphate.

Crystal structure: Although the hexagonal dense stacking structure of lithium manganese iron phosphate is safe and stable,

it cannot form a continuous Co-O-Co structure like lithium cobalt oxide materials due to the lack of a continuous FeO6 (MnO6) tetrahedral network in the material,

but rather through PO4 tetrahedral connections.

The material has poor conductivity and poor high current discharge performance.

And these polyhedra form interconnected three-dimensional structures, limiting the movement of lithium ions in one-dimensional channels.

Metallic properties: Manganese has relatively weak conductivity.

Due to the above reasons, the transition energy gap of electrons in lithium manganese iron phosphate is as high as 2eV (the transition energy gap of lithium iron phosphate is 0.3eV),

which has the disadvantages of low conductivity and ion mobility.

(2) When the manganese doping ratio is too high, the Taylor effect occurs, which affects the cycle life and cycle stability.

When the manganese content is too low, the platform voltage of lithium manganese iron phosphate material does not increase significantly, which affects the energy density of the material.

When the manganese content is too high, the Taylor effect is prone to occur,

which means that during the charging and discharging process, manganese ions dissolve and deposit on the negative electrode surface,

damaging the SEI film and continuously regenerating and repairing it, thereby consuming a large amount of active lithium and causing capacity loss;

Manganese leaching reacts with electrolyte, affecting material stability and capacity retention.

In addition, manganese has poor conductivity and is prone to polarization, which can also lead to a decrease in cycle life.

(3) The low compaction density affects the energy density.

According to the official account of the advanced battery material,

the compaction density of the current mainstream lithium manganese iron phosphate is 2.3g/cm3, and some of it reaches 2.4g/cm3,

while the compaction density of lithium iron phosphate can reach 2.6 g/cm3, and the powder compaction of lithium manganese iron phosphate is basically the same as the electrode plate compaction.

(4) The dual voltage platform requires BMS management capabilities.

There is a significant difference in the discharge voltage between iron and manganese in the lithium manganese phosphate system, resulting in a dual voltage plateau during the discharge process,

which may cause a power drop in the battery during the discharge process. The dual voltage platform requires BMS management capabilities.

Image: Classification of Lithium Battery Positive Electrode Materials, Source: Guohai Securities

From the perspective of energy density, ternary>LMFP>LFP. The voltage platform of LMFP is 4.1V, which is higher than LFP's 3.4V.

According to the energy density=gram capacity x voltage, the theoretical energy density of LMFP is 21% higher than LFP, but there is still a significant gap compared to ternary materials.

Therefore, LMFP is not positioned as a substitute for ternary materials.

From the perspective of compaction density (positively correlated with actual energy density), ternary>LFP>LMFP.

The LFP process is relatively mature, with a compaction density range of 2.1-2.6g/cm3, and a few leading enterprises can achieve a level of 2.6g/cm3.

The current compaction density of LMFP is 2.3-2.5g/cm3 (the company's product is 2.2-2.3), which is lower than LFP, and there is still room for improvement with the maturity of the process.

Ternary materials have a relatively high compaction density due to their high true density.

From a security performance perspective, LFP>LMFP>ternary. Due to the poor stability of ternary materials, lattice collapse is prone to occur at high temperatures, resulting in poor safety.

Due to the poor high-temperature performance of manganese element, LMFP has slightly lower safety performance than LFP, but both have stronger safety than ternary.

From the perspective of low-temperature performance, ternary>LMFP>LFP.

According to data from Giant Lithium Battery, the capacity retention rate of ternary materials at -20 degrees is generally above 80%.

However, LFP and LMFP have lower conductivity and lower low-temperature performance compared to ternary materials.

Taking the German nano LFP product as an example, the capacity retention rates of DY-1 and DF-5 at -20 degrees are 73% and 60%, respectively,

which is lower than the 75% retention rate of LMFP product.

This is mainly due to the fact that LMFP has smaller primary particles than LFP and a shorter Li+transport path.

From the perspective of cycle life, LFP>LMFP>ternary.

Due to the good lattice stability of olivine type, the cyclic performance of LFP and LMFP is better than that of ternary materials.

From the capacity retention rate of 2000 cycles, the Scoland LMFP is 88.7%, slightly lower than the 89.4% of the German DY-3.

Mainly due to the low maturity of LMFP technology (due to the Ginger Taylor effect causing manganese leaching to damage the SEI film and accelerate degradation), the current cycle life has not reached the level of LFP.

Figure: Crystal Structure and Performance Comparison of Lithium Iron Phosphate and Lithium Manganese Iron Phosphate, Source: Zheshang Securities

Summary: Against the backdrop of the rise of lithium iron phosphate, manganese iron lithium phosphate, as a new generation of iron lithium materials,

has achieved a balance between safety and cost, improved energy density, and broad market prospects driven by technology.

It has gained preliminary industry consensus. Compared with lithium iron phosphate, lithium manganese iron phosphate has higher potential and energy density.

Compared with ternary materials, lithium manganese iron phosphate has higher safety and cycle life, as well as lower cost.

With the continuous maturity of modification technologies such as ion doping, carbon coating, nanomaterialization, lithium supplements, conductive agents,

and composite material technologies such as ternary materials, the conductivity, cycle life, rate performance, low-temperature performance, energy density,

and other properties of lithium manganese iron phosphate have been improved and enhanced.

The production process is continuously optimized to achieve lower costs, driving the cost-effectiveness advantages of lithium manganese iron phosphate to become increasingly prominent.

It is expected to quickly penetrate the field of power batteries and achieve large-scale marketization.

2、Technology

Lithium manganese iron phosphate technology is similar to lithium iron phosphate technology in that the equipment is roughly the same and can be used interchangeably,

both requiring a synthesis process. Therefore, synthesis technology is key, and currently mainly includes two systems: solid-phase method and liquid-phase method;

At the same time, due to the more complex structure of lithium manganese iron phosphate, there are problems such as crystal structure distortion after adding manganese,

which affects cycling and rate performance. Therefore, modification technology is also included in the production process of lithium manganese iron phosphate.

(1) The synthesis technology of lithium manganese iron phosphate: the semi liquid and semi solid phase method has greater potential for performance.

Manganese iron lithium and iron lithium both belong to the phosphate system, with similar preparation processes.

The solid-phase method is simple and suitable for industrial production,

while the liquid-phase method is more complex and suitable for structural design and modification operations, resulting in better product performance.

Manganese iron lithium phosphate has a heterogeneous crystal structure,

while the liquid-phase method is conducive to forming a structure with more manganese inside and less manganese outside, reducing the problem of manganese overflow.

However, unlike the iron lithium industry, there is mature iron phosphate as a precursor;

In the early stages of the development of the manganese iron lithium industry,

there were no standard precursors, and positive electrode companies had to prepare them themselves, which increased the industry's technical barriers.

At present, there are three main technical routes for the preparation of lithium manganese iron phosphate:

The first technology: basically using the "solid-phase method" process route of lithium iron phosphate: mixing solid raw materials that do not react with each other,

grinding (to 80 nm), drying, sintering, and crushing to obtain lithium manganese iron phosphate.

The solid-phase method is simpler and more suitable for industrialization, but it is not easy to mix and requires higher requirements for subsequent modification.

The second technique is to use all water-soluble raw materials to prepare lithium manganese iron phosphate through a high-temperature and high-pressure "hydrothermal synthesis" method,

followed by drying, sintering, and crushing to obtain the product.

Manganese iron requires atomic level mixing, so liquid-phase method is naturally more suitable for the production of lithium manganese iron and has better performance.

The third route is the "semi liquid and semi solid" method.

Under normal temperature and pressure, the raw materials are chemically reacted to produce compound intermediate compounds,

which are dried, sintered and crushed by (spray) to obtain products.

Figure: Comparison of main production processes for lithium manganese iron phosphate (German side to self increase fundraising proposal, each enterprise's route comes from patents)

(2) Modification technology is one of the key factors in accelerating industrial development. Based on the defects of LMFP materials,

the development of modification technology is crucial in accelerating industrial development.

The main modification technologies include nanomaterialization, carbon coating, ion doping, etc.

Nanotechnology: improves conductivity and enhances charge and discharge capacity.

By reducing the particle size of the material to the nanometer level, on the one hand, the migration path of lithium ions can be shortened, improving the efficiency of lithium ion migration.

On the other hand, by increasing the specific surface area of the material,

the contact between the material and the electrolyte can be more complete, reducing the electrode interface impedance and ultimately improving the conductivity performance.

In addition, the improvement of lithium ion migration efficiency also helps to reduce electrode polarization, thereby enhancing the charge discharge capacity and rate performance of the material.

Nanotechnology is the most fundamental and effective way to enhance lithium manganese iron phosphate, but it also has certain negative effects.

As the particle size of the material decreases, serious particle agglomeration will occur during the production and pulping process,

affecting the uniformity of the material, reducing the compaction density of the electrode, and thus affecting the performance of the battery.

Therefore, it is often used in combination with other modification methods. Representative companies: Scoland, DFNano.

Carbon coating: significantly improves conductivity, inhibits manganese leaching, and enhances cycling stability.

By uniformly coating the carbon coating on the surface of the material (layered coating),

a fast conductive network is constructed to provide effective channels for Li+ion diffusion,

while avoiding crystal particle growth and aggregation, thereby improving the external conductivity of the material.

In addition, carbon coating can also inhibit the leaching of manganese ions and reduce the impact of the Taylor effect on battery capacity and cycling stability.

Common carbon sources include glucose, sucrose, citric acid, graphene, carbon nanotubes, etc.

Ion doping: improves conductivity, and some ions can inhibit the leaching of manganese ions.

By doping ions into the material, defects can be generated in the original lattice,

expanding the Li+diffusion channel and increasing the carrier density of the material, thereby improving the internal conductivity of the material.

Among them, the doping of Mg2+can not only improve conductivity, but also improve the capacity and cycling stability of materials by suppressing the Taylor effect.

Currently, the method of doping Mg2+is widely used and researched.

Triple reuse: creating a diversified product line with complementary performance.

Lithium manganese iron phosphate is mainly used for power and household energy storage, replacing high-pressure lithium iron phosphate;

Mixing mainly refers to mixing with ternary materials,

including using ternary materials as the main component and manganese iron lithium as a supplement to improve safety performance,

or using manganese iron lithium as the main component and ternary materials as a supplement to increase energy density.

Lithium manganese iron phosphate has a high voltage platform and is compatible with ternary systems, making it feasible for reuse.

According to Gao Gong Lithium Battery, high nickel+manganese iron phosphate lithium not only surpasses most medium and low nickel products in comprehensive performance,

but also has significant cost advantages.

Therefore, after optimizing the battery cell design, if all high nickel+manganese iron lithium positive electrode materials are used, it can replace the existing medium nickel ternary scheme,

achieving the optimal cost and performance of the battery cell/PACK end.

According to "Research on the Composite Ternary System and Composite Method of Lithium Manganese Iron Phosphate",

by combining the poorly conductive lithium manganese iron phosphate material with the highly conductive ternary material,

the battery equipped with this composite positive electrode material can have both the high energy density and high power characteristics of ternary materials,

as well as the high safety and low cost advantages of lithium manganese iron phosphate.

Other methods include microstructure control, precursor homogenization, process improvement, positive electrode compensation, etc.

Table: Comparison of main modification processes for lithium manganese iron phosphate

Summary: In the production and synthesis process of lithium manganese iron phosphate, in addition to the selection of raw materials and process routes,

modification methods such as doping and coating are also combined to obtain products that meet the requirements of cycling performance,

compaction density, capacitance, product stability, cost, and compatibility with other positive electrodes.

It is difficult to solve the problem by a single process method, and the application technology threshold in the field of power batteries is very high.

Currently, the technical route has not been fully finalized, so material suppliers are required to have strong technical development capabilities.

3、Application scenarios and market space

(1) Short term transition market - electric two wheelers: The trend in the two wheeler battery industry is that lithium batteries can replace lead-acid batteries.

Looking at the breakdown of lithium battery materials, driven by the high-end car market (LMFP takes into account both volumetric energy density and safety performance),

Xingheng+Tianneng actively promotes the increase of manganese iron lithium. In 2022, LMFP installed 0.6 GWh in two wheelers and has already been used in small quantities.

It is expected to install 6.8 GWh in 2025, with a demand of 15000 tons and a market size of 1.2 billion yuan.

LMFP materials are currently mainly suitable for electric two wheelers and three wheelers.

Due to the consistency of LMFP discharge platform and LMO (lithium manganese battery), the charge components do not need to be changed too much when used together,

and it has excellent safety, low temperature characteristics, cycling characteristics, and cost-effectiveness.

Therefore, in the two wheeler lithium battery market, LMFP and LMO are mostly mixed and used, and corresponding battery products have been launched by Tianneng Co., Ltd. and Xingheng Power.

Table: Comparison of Positive Electrode Material Parameters for Two Wheel Vehicle Batteries, Source: Guohai Securities

According to the Internet observation community and the official website of Xiaoniu Electric,

the energy density of Tianneng's super energy lithium manganese iron battery is 17% higher than that of lithium iron phosphate battery,

and it still has a capacity retention rate of 85% at a low temperature of -20 ℃.

At present, the product is used in many series of Xiaoniu Electric GOVAF0, UQi+, etc.

Xingheng Power and Yadi jointly released the FAR Expedition series lithium battery,

which uses Xingheng's second-generation mixed doped single crystal lithium manganese oxide at the material level.

In terms of 3C digital, Xingheng Power and Newman have jointly developed a new outdoor mobile power product,

Newman S series, which has multiple advantages such as high safety, long cycle life, large capacity, and super bidirectional fast charging.

Comparison of cost-effectiveness of lithium manganese iron phosphate, lithium iron phosphate, and sodium ion batteries:

When the industry matures, the cost of lithium and sodium batteries is comparable,

but lithium batteries, especially LMFP batteries, have higher energy density and are more suitable for small power and power battery use.

Sodium batteries: are beginning to form an "industrialization".

According to a research report by a securities firm,

when sodium batteries are not mass-produced, assuming that the prices of positive electrode materials, hard carbon,

and electrolyte are 60000 yuan/ton, 65000 yuan/ton, and 90000 yuan/ton, respectively,

the estimated cost of sodium battery cell materials is 0.53 yuan/Wh. 2) After the mass production of sodium batteries:

under optimistic expectations, assuming that the unit usage of main materials remains the same as before mass production,

the unit prices of some main materials will decrease. The unit prices of positive electrode, negative electrode, and electrolyte are 35000 yuan/ton, 30000 yuan/ton, and 25000 yuan/ton respectively.

According to calculations, the cost of sodium battery cells is 0.29 yuan/Wh, while under neutral expectations,

the material cost of sodium battery cells is about 0.32 yuan/Wh, a decrease of 39% -45%.

Lithium iron phosphate battery: The price of square lithium iron phosphate batteries is expected to drop to a maximum of 0.35 yuan/Wh.

Cost composition of battery cells: Generally speaking, the cost of positive electrode materials accounts for more than 30%,

the cost of negative electrode materials and electrolytes accounts for 10% -20%,

the cost of separators accounts for about 10%, and the total cost of the four main materials exceeds 60%.

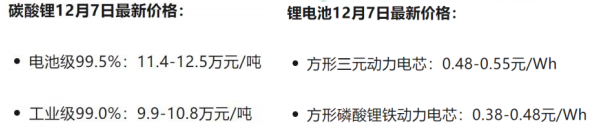

Market data shows that from the beginning of the year to now,

the price of the four main materials has generally fallen by more than 50%, and the cost of the four main materials will account for less than 40%.

The price of lithium carbonate has bottomed out, and its impact on battery cell costs is not significant.

Taking lithium iron phosphate as an example, 1GWh requires 2200-2500 tons of lithium iron phosphate, and 0.25 tons of lithium carbonate per ton of lithium iron phosphate.

Therefore, 1GWh requires approximately 550-625 tons of lithium carbonate,

which means that each ton of lithium carbonate can produce 1703578Wh of batteries. For every 50000 yuan/ton change in lithium carbonate

it affects the price of battery cells by 0.029 yuan/Wh.

Prediction of lithium carbonate price trend:

In 2024, there will be a global surplus of lithium resources,

and it is highly likely that high cost marginal production capacity will need to be squeezed out through price declines to achieve balance sheet repair.

Lithium prices may need to drop to around 70000-80000 yuan/ton to clear about 15% of high cost production capacity.

Lithium manganese iron phosphate battery:

According to the announcement of German Nanotechnology, compared with LFP, LMFP has a theoretical energy density 21% higher,

and the actual energy density can be increased by 15% -20%, reducing the overall cost of battery packs with the same amount of electricity by 10% -15%.

With the reduction of production costs brought about by process optimization, LMFP will gradually show a competitive advantage.

It is expected that the price of lithium carbonate will be less than 120000 yuan/ton, and lithium manganese iron phosphate batteries have a cost advantage compared to sodium batteries.

(2) Mid term main high-volume market - power vehicles:

With the continuous improvement and optimization of the disadvantages of LMFP materials (insufficient conductivity, unstable voltage performance, BMS system),

and the finalization of on-board batteries such as M3P, LMFP materials and batteries will rapidly increase in the power field.

LMFP+ternary hybrid battery can solve the problems of ternary safety and high cost, with higher energy density than LFP battery.

It has great potential for application in the field of power batteries and is expected to have a market share of over 50%.

In terms of material suppliers: According to the announcement from German Nano,

the downstream application of the company's manganese iron lithium phosphate products is mainly in the new energy vehicle market,

supplemented by the energy storage market.

The company expects that manganese iron lithium phosphate is expected to achieve large-scale application in downstream new energy vehicle models by 2023,

and both pure and mixed use solutions have been verified by customers.

On December 6th, a reporter from Beike Finance of the New Beijing News learned from the official website of German Nano that during a survey conducted by investment institutions,

German Nano stated that it has built a production capacity of 110000 tons of lithium manganese iron phosphate and has achieved commercial application;

At present, bulk supply for loading has begun, and the shipment volume is gradually increasing according to the pace of customer demand.

According to the announcement from Rongbai Technology, in Q1 2023,

the company (Tianjin Skyland) has completed the upgrading and transformation of its existing production capacity and passed multiple customer certifications.

Currently, it is in the inspection stage of lithium manganese iron phosphate battery vehicles.

Previously, the company expected that lithium manganese iron phosphate could be mass-produced in some vehicle models by 2023.

Hunan Yuneng: Lithium manganese iron phosphate products have entered the trial production stage.

The research and development of lithium manganese iron phosphate products are progressing smoothly and have entered the trial production stage.

The powder compaction, magnification and other performance indicators are excellent, and we are actively promoting customer certification.

The production line can be flexibly switched.

In terms of downstream applications,

the Ningde Times M3P battery has landed on some models of the Zhijie S7 and Xingtu (according to the enterprise and product announcements of the Ministry of Industry and Information Technology,

the Chery Xingtu Xingjie and Zhijie S7 models use Ningde Times ternary lithium-ion and manganese iron phosphate lithium batteries).

Moreover, the lithium manganese iron phosphate battery pack will not only be equipped on the upgraded Model 3,

but also become a platform solution for Tesla, and is expected to be adopted by future Model Y models. It is expected that future Model 3 models will also be equipped with CATL M3P batteries.

In May of this year, Guoxuan High Tech released the L600 Qichen battery cell and battery pack using the manganese iron lithium phosphate technology route.

It is reported that the L600 Qichen battery cell can achieve an energy density of 240Wh/kg and fast charging in 18 minutes, and is expected to be mass-produced in 2024.

Xinwangda stated on the investor interaction platform that the company is currently developing manganese iron phosphate lithium batteries,

with an energy density of up to 235Wh/kg and overall performance at the forefront of the industry. It has been recognized by customers and is undergoing industrial development work.

(3) Long term - Energy Storage Market: In the long term, due to better low-temperature characteristics and cycle life,

LMFP batteries are expected to gradually penetrate the energy storage market, and the blending ratio is expected to increase.

According to the forefront of energy storage, the cycle life of lithium iron phosphate is between 2000 and 6000 times,

while the cycle life of lithium manganese iron phosphate is between 2000 and 3000 times, which hinders its application in the field of energy storage.

From the progress in the energy storage field of related companies, Xingheng Power has launched the BRICS battery for the "dynamic storage market",

mainly supplying the electric vehicle and household storage markets.

Table: Market Space Calculation

At present, lithium manganese iron phosphate is mainly used in the field of low-speed two wheeled vehicles, and LFMP will have small batch applications in the field of four-wheel vehicles in 2023.

The overall shipment volume of lithium manganese iron phosphate in 2023 is about 3000 tons (according to reports, the shipment volume of 2023H1 is nearly 1000 tons, accounting for 70%).

In the future, it will mainly replace LFP and be compounded with ternary batteries.

It is expected that the global demand for LMFP materials will be 320000 tons in 2026, with a market space of nearly 25 billion yuan calculated based on a single ton of 80000 yuan.

4、Industry competition pattern

(1) Giants in the field of positive electrode materials have entered the market one after another,

and even traditional iron phosphate production lines can be transformed and entered, intensifying industry competition.

Currently, most manufacturers' products are in the early stage of product development, and the introduction of two wheelers is relatively easy.

In the field of power batteries, only CATL has a clear plan for on-board product models,

and material suppliers such as DFNano and Hunan Yuneng have also received good feedback.