Lithium manganese iron phosphate: industrial singularity with promising future

Aug,07,24

Manganese iron mutual solubility enhances energy density and creates an upgraded version of lithium iron phosphate

Lithium manganese iron phosphate: Manganese iron is miscible, increasing energy density and creating an upgraded version of lithium iron phosphate

Lithium manganese iron phosphate is a solid solution of lithium iron phosphate and lithium manganese phosphate.

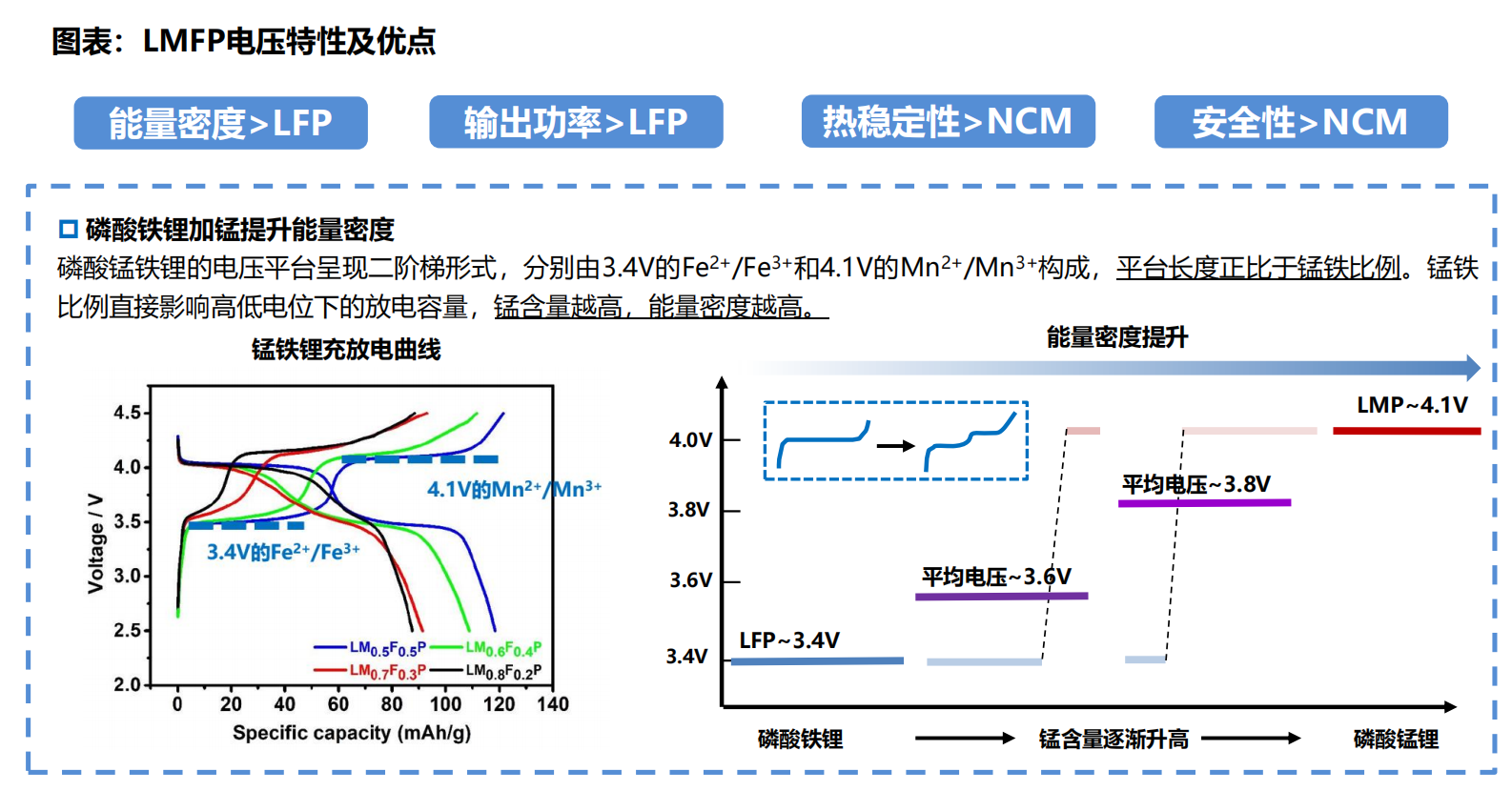

The manganese element enhances the voltage platform, thereby increasing the energy density of the iron lithium system.

Lithium manganese iron phosphate (LMFP) maintains the stable olivine structure of lithium iron phosphate

and introduces high voltage plateau lithium manganese phosphate (4.1V) to enhance the energy density of the iron lithium system.

Advantage: The voltage platform is increased, and compared with iron lithium, the energy density can be increased by up to 21%

The voltage platform of manganese element is high, and the energy density is correspondingly increased after solid solution.

Lithium manganese iron phosphate has a dual discharge platform, with lithium manganese phosphate discharging first and then lithium iron phosphate discharging.

The higher the proportion of manganese element, the higher the average voltage of the positive electrode, and the higher the energy density and output power of the battery.

In theory, a manganese iron ratio of 6/4 can improve performance by 10-15%, and when all manganese is replaced, it can increase performance by 21%.

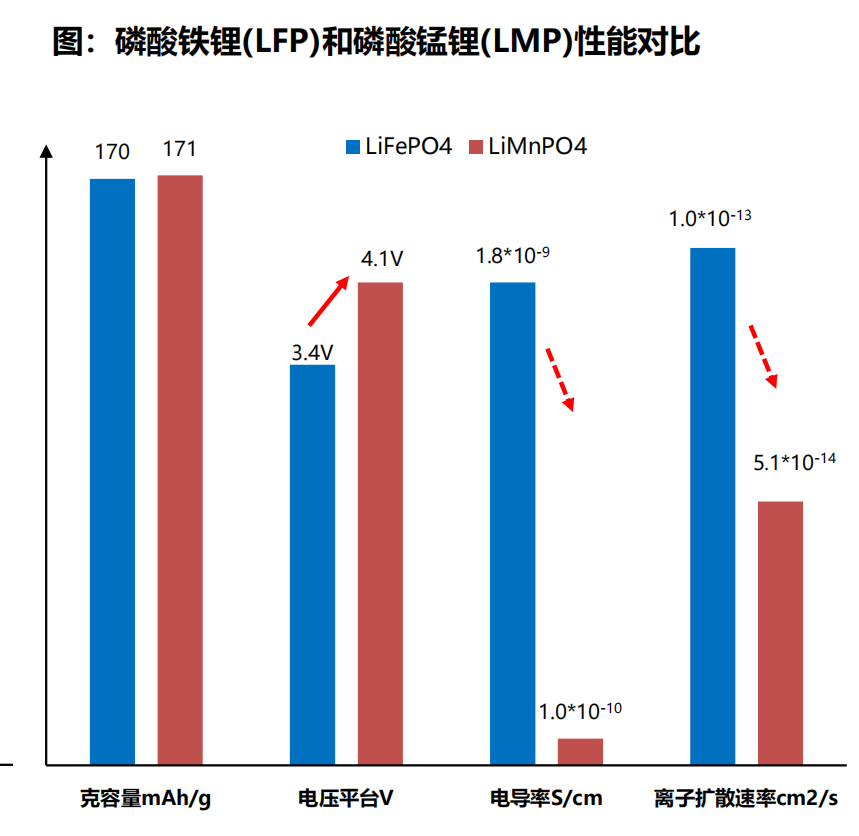

Disadvantage: After adding manganese, the crystal structure undergoes distortion, and the cycling and rate performance deteriorate

The structural stability of lithium manganese iron phosphate is poor, and the cycling and rate performance of the battery deteriorates.

After the mutual dissolution of manganese and iron, the material may experience crystal structure distortion,

and manganese leaching may occur during battery cycling, reacting with the electrolyte and affecting the cycle life.

At the same time, the conductivity and ion diffusion coefficient of the material are poor, which affects the rate performance.

The use of nanomaterials and other modification methods can basically solve the electrochemical problems of materials, but it will reduce the compaction density of materials.

Proportion trend: The proportion of manganese and iron is the key to determining material properties, and long-term evolution towards high manganese content

The higher the manganese content, the greater the increase in energy density, but there will be a decrease in capacity and a decline in cycle life.

There is no unified optimal standard for the ratio of manganese to iron in the industry.

In the long run, the high manganese ratio is an evolving trend, but the process challenges are enormous.

Currently, the mainstream ratio in the industry is LMFP with a manganese to iron ratio of 6/4, which has good comprehensive performance.

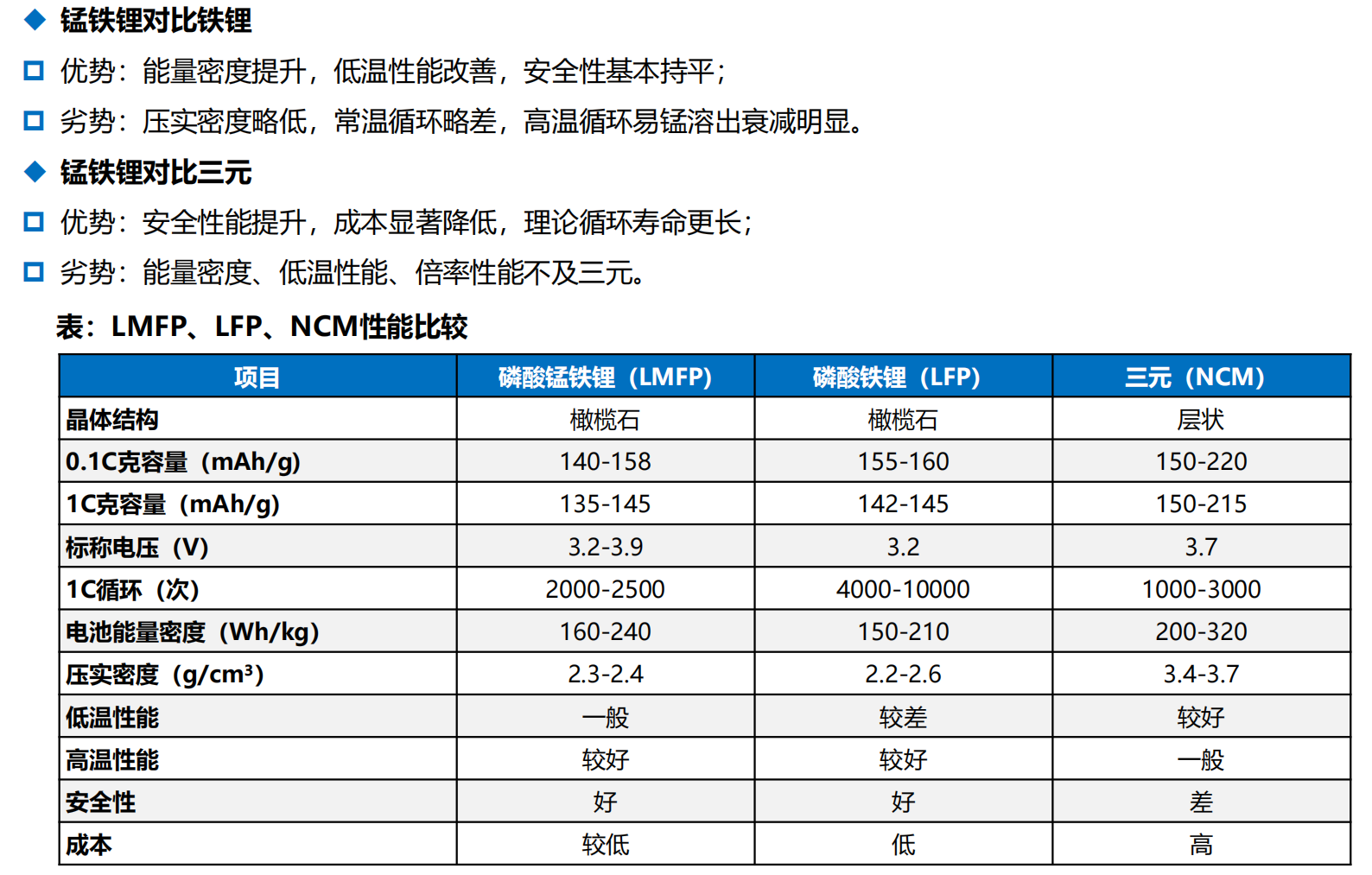

Performance: Energy density/low-temperature performance better than iron lithium, safety/economy better than ternary

Manganese iron lithium compared to iron lithium

Advantages: Improved energy density, improved low-temperature performance, and relatively stable safety;

Disadvantage: The compaction density is slightly low, the room temperature cycling is slightly poor,

and the high temperature cycling is prone to manganese leaching and significant attenuation.

Manganese iron lithium compared to ternary

Advantages: Improved safety performance, significantly reduced costs, and longer theoretical cycle life;

Disadvantage: The energy density, low-temperature performance, and rate performance are not as good as three yuan.

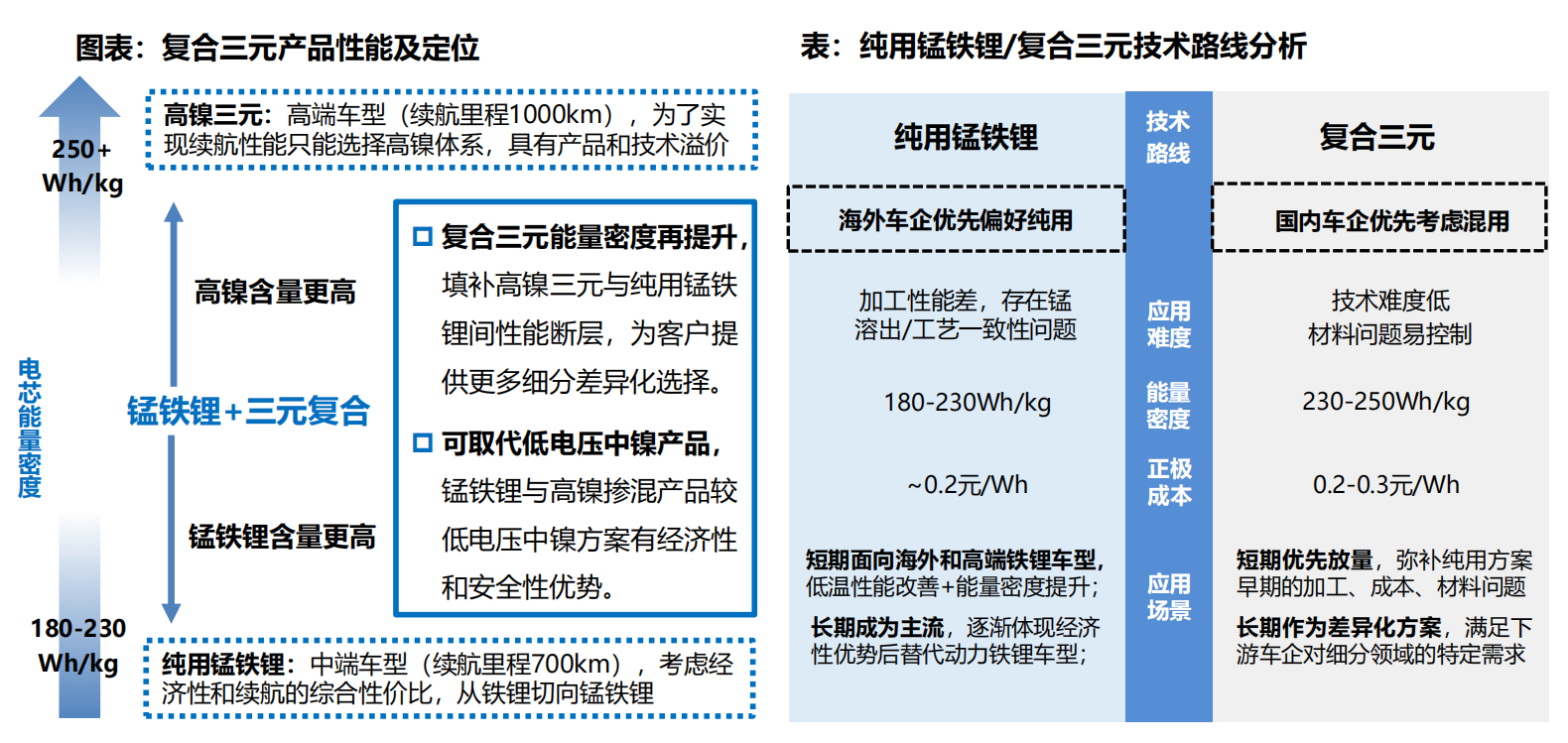

Route: Mixed use is currently the mainstream route, pure use is more economical, and is expected to become a long-term trend

Manganese iron lithium voltage and ternary matching can provide new material solutions for composite materials.

The voltage of manganese iron lithium is matched with high nickel ternary, and after compounding, a product that combines safety and high energy density can be obtained,

and a series of flexible solutions can be formed to meet terminal needs. Currently, the Ningde Times hybrid solution has been adopted in the Chery Intelligent S7 model.

Pure use is more cost-effective and is expected to become a long-term trend.

The pure use route will initially target overseas customers and increase the volume of high-end lithium iron vehicles in the short term.

With continuous technological breakthroughs, the economic advantages brought by the increase in energy density will gradually be reflected,

and it is expected to fully replace the power lithium iron scenario.

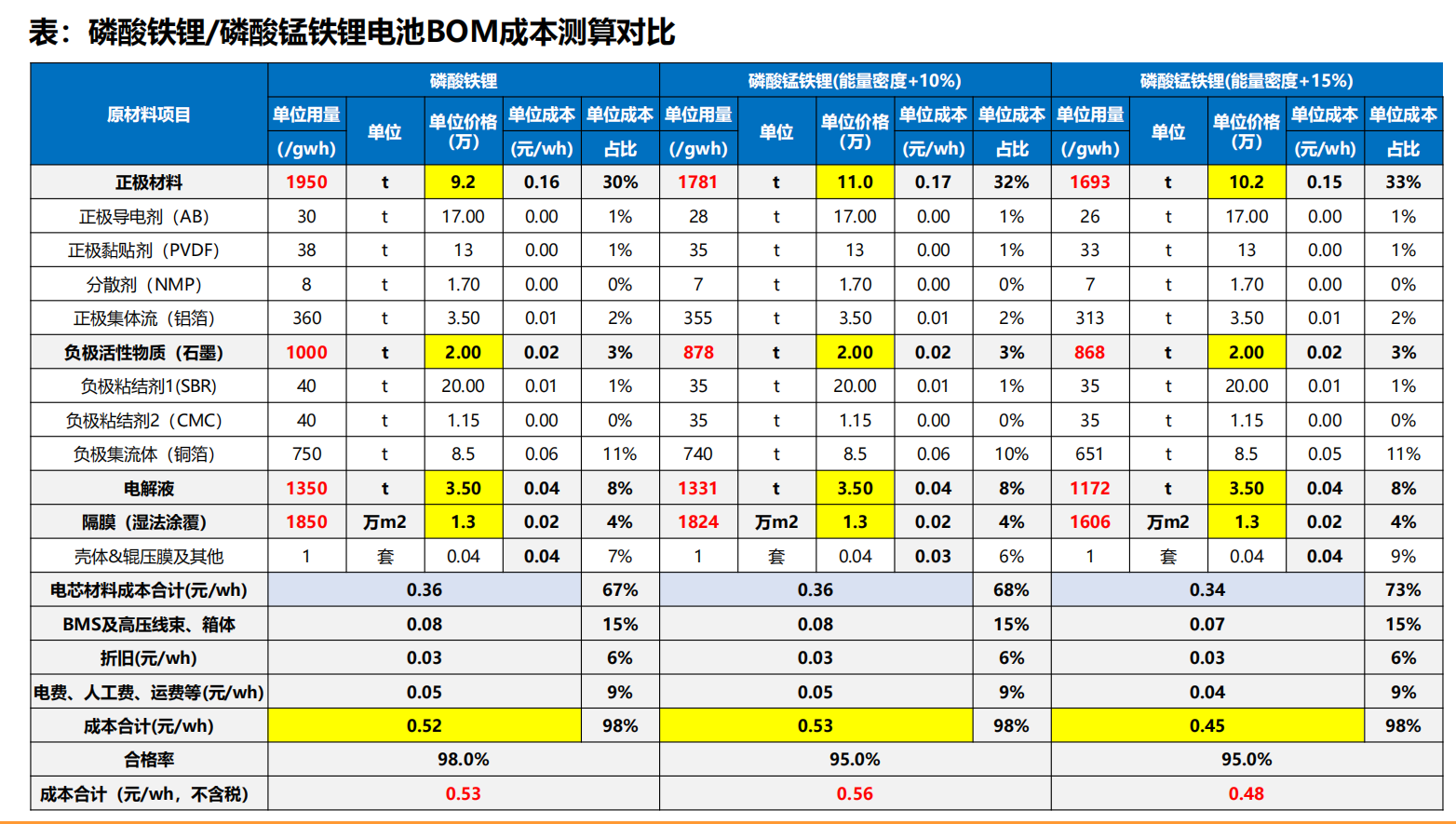

Economy: The energy density is increased by 10-20%, and the cost of the positive electrode is 10% higher than that of iron lithium

The raw material cost of lithium manganese iron phosphate is slightly higher than that of lithium iron.

Manganese iron lithium requires the use of manganese sources instead of iron sources (Mn 14000/ton compared to Fe 4000/ton),

and there are more types of additives, resulting in a 5% increase in raw material costs.

Iron and manganese require atomic level mixing, and the increase in process requirements leads to an increase in processing costs.

We speculate that the processing cost of manganese iron lithium is 10% higher than that of iron lithium,

and the price of positive electrode material is around 100000 yuan/ton (250000 yuan/ton for lithium carbonate), which is about 10% higher than the overall premium of iron lithium.

Economy: The decrease in unit consumption reduces the cost of Wh and has the potential to replace power lithium iron in the long run

The increase in energy density of lithium manganese iron phosphate reduces unit consumption,

and it is expected that the cost per Wh will decrease by nearly 10% in the future.

In the initial stage, assuming a 10% increase in energy density of manganese iron lithium,

we estimate that the cost of battery cells is slightly higher than that of iron lithium;

In the long run, assuming a 15% increase in energy density of lithium iron manganese,

we estimate that the cost of battery cells will decrease by about 10% compared to lithium iron.

This has significant economic advantages in the power sector, and we are optimistic about the substitution of lithium iron manganese.

Application scenario analysis: Two wheeled vehicles are the first to land, replacing mid to low end power scenarios

Power scenario: pure manganese iron lithium economic advantages+low-temperature performance improvement,

with a large number of iron lithium vehicle models penetrating after technological progress;

The energy density of the composite route is further improved to meet the differentiated needs of terminals.

Two wheeled vehicle scenario: pure use/mixed use, with a short verification cycle and being the first to implement.

Energy storage scenario: unable to meet long-term cycling requirements in the short term, with low penetration potential.

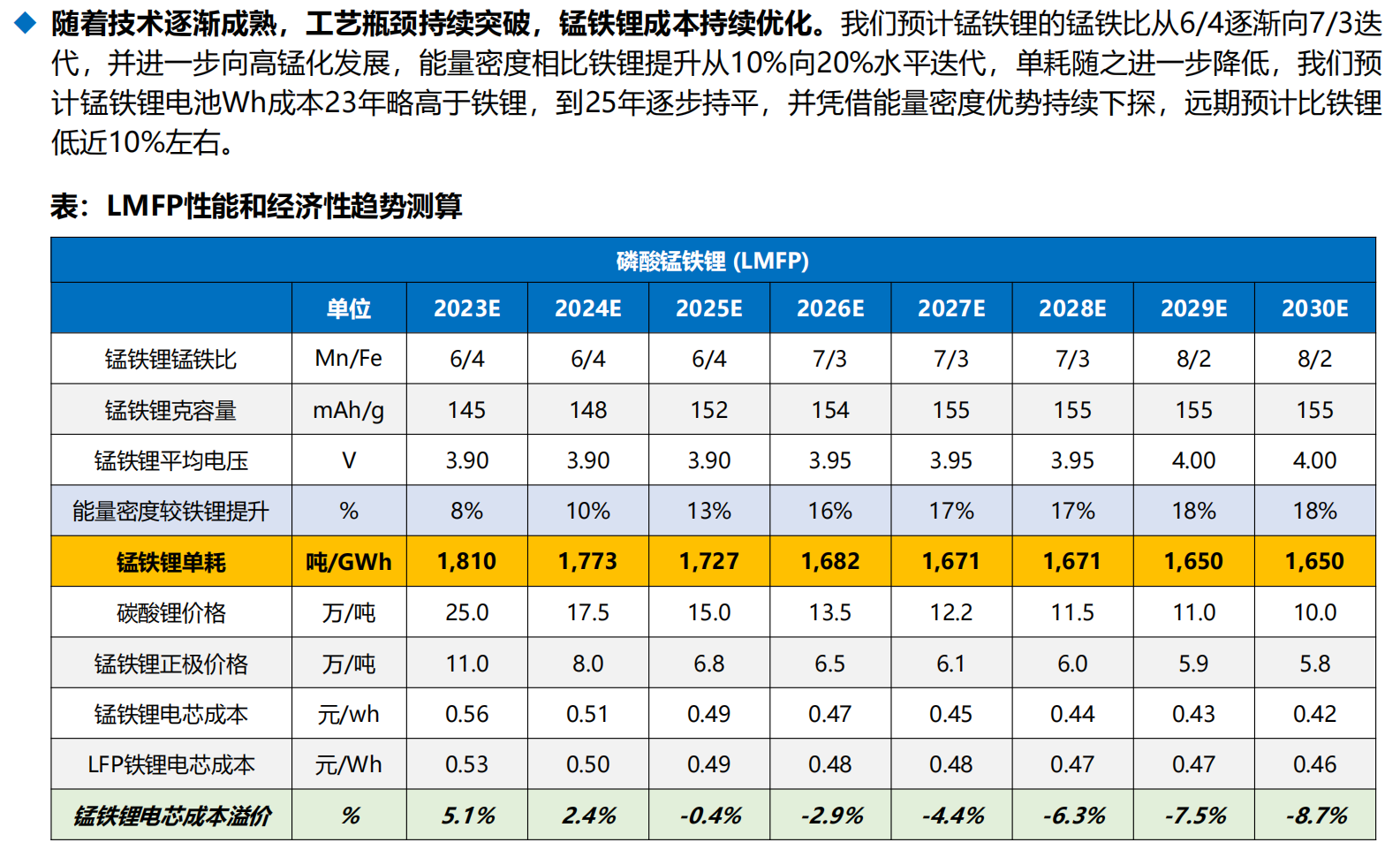

Cost iteration: continuous technological breakthroughs, increased energy density, and continuous cost optimization

With the gradual maturity of technology and continuous breakthroughs in process bottlenecks, the cost of manganese iron lithium continues to be optimized.

We expect the manganese to iron ratio of manganese iron lithium to gradually iterate from 6/4 to 7/3, and further develop towards high manganese content.

The energy density will increase from 10% to 20% compared to iron lithium, and the unit consumption will further decrease.

We expect the Wh cost of manganese iron lithium batteries to be slightly higher than that of iron lithium in 23 years, gradually stabilize in 25 years,

and continue to decline with the advantage of energy density. In the long run, it is expected to be nearly 10% lower than that of iron lithium.

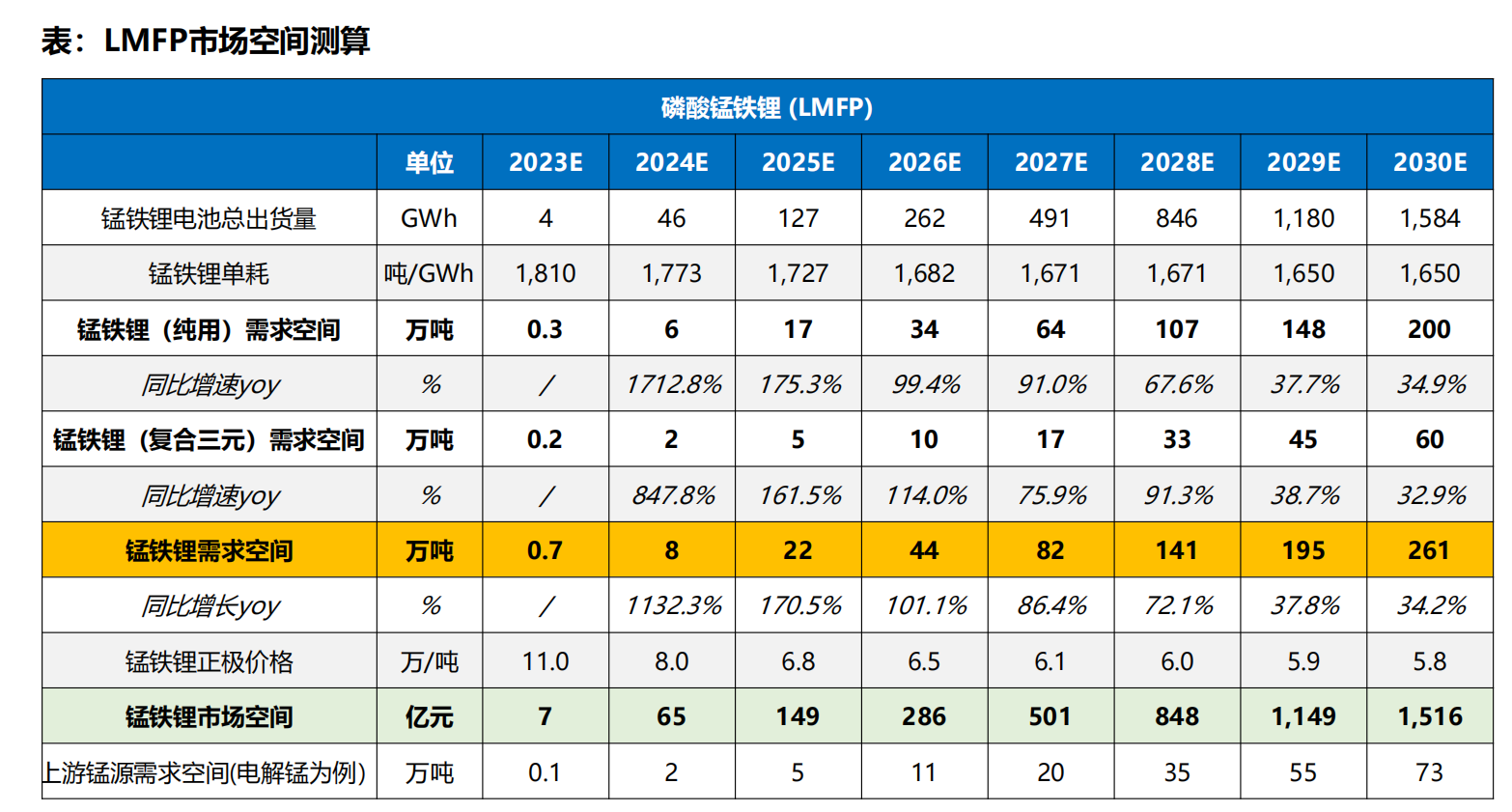

Spatial calculation: Gradually penetrate the ternary system of dynamic iron lithium and medium nickel, with a penetration rate of 5-10% over 25 years

We estimate that the 25 year penetration rate of lithium manganese iron is 5-10%, and the battery demand exceeds 120GWh.

Manganese iron lithium, with its cost-effectiveness advantage, is expected to gradually replace iron lithium and medium nickel ternary batteries in the power field.

We expect the power penetration rate of manganese iron lithium to be 5-10%/30+% by 25/30, including 10-15%/50% for iron lithium and 3%/15% for ternary batteries.

The battery demand is 127/1584GWh.

Space calculation: The space for positive electrode materials is vast, with a demand of over 20/2.6 million tons in 25/30

With the rapid penetration of manganese iron lithium, there is a strong demand for upstream materials.

We expect the demand for manganese iron lithium cathode materials to exceed 20/2.6 million tons in the next 25/30 years,

corresponding to a market space of over 140/150 billion yuan.

At the same time, manganese iron lithium will boost the demand for manganese sources,

and it is expected that the demand for upstream manganese sources will reach 5/730000 metal tons by 25/30.

LMFP Summary: Balancing the safety of iron and lithium with cost advantages, taking energy density to the next level

Lithium manganese iron phosphate is a high-energy density version of lithium iron,

which is expected to overcome mass production problems and increase production in the second half of 2023.

The M3P battery hybrid solution will be launched for the Zhijie S7 in August,

and it is expected that the pure use solution will be launched for the Tesla Model 3 facelift in the second half of the year,

which will become a catalyst for the explosive growth of manganese iron lithium.

Economic advantage+performance improvement dual core drive, with strong long-term penetration power in the power iron lithium scenario.

After the mass production problem is solved, battery companies and car companies will immediately follow up,

and currently the top companies are basically in the process of testing and verification.

The process technology is becoming increasingly mature, and the solid/liquid phase method routes are parallel

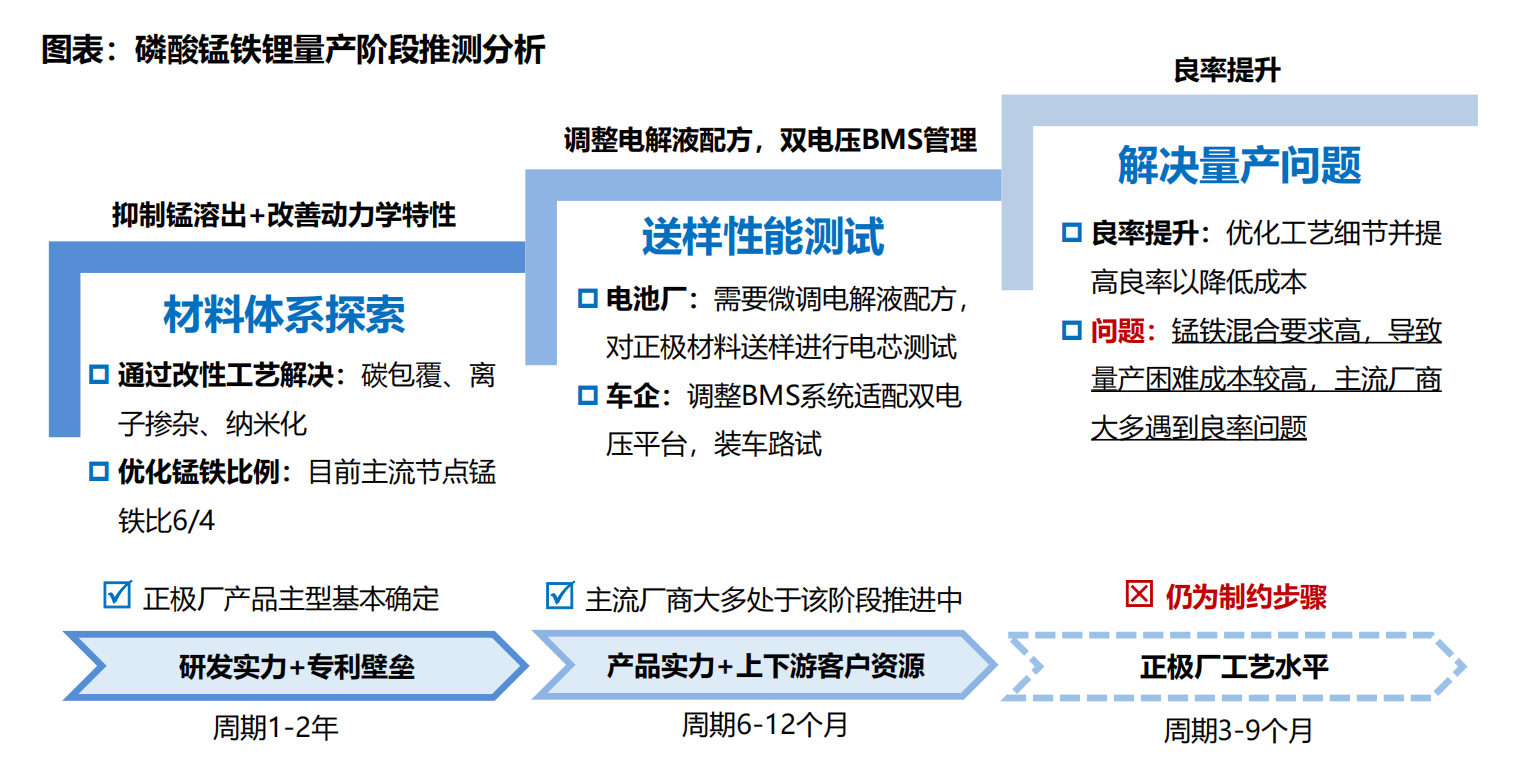

Modification: Lithium manganese iron requires modification treatment, and the mass production yield still needs to be improved

When manganese iron lithium is cycled at high temperatures, manganese leaching is prone to occur and modification treatment is needed.

The positive extreme can be initially solved through carbon coating, ion doping, and nanomodification strategies,

and there is still room for improvement in high-temperature cycling at present.

The electrolyte formula needs to be adjusted at the battery cell end to adapt to the BMS system.

Manganese iron requires atomic level mixing and high crystallinity, and the mass production yield needs to be improved.

The requirements for mixing and crystallinity of manganese iron lithium precursors have increased, and the process needs to be modified accordingly.

Currently, the yield is still lower than that of iron lithium.

Positive electrode modification: a combination of three strategies: carbon coating, ion doping, and nanomaterialization

The combination of carbon coating, ion doping, and nano modification strategy jointly solves the problem of manganese iron lithium materials.

Carbon coating and nanoscaling are commonly used modification methods for iron lithium materials to obtain better kinetic properties and improve rate performance.

Ion doping is a unique modification strategy for manganese iron lithium materials, mainly used to suppress manganese leaching and enhance ion diffusion,

and can be doped with one or more elements.

Cell design: electrolyte formula or reference to high nickel ternary, data-driven research and development to assist material development iteration

The modification of manganese iron lithium electrolyte can draw on the know how of ternary high nickel.

The voltage range and oxidation-reduction reaction of manganese iron lithium are similar to those of high nickel.

The problem of manganese leaching can be solved by referring to the solution of nickel/manganese leaching in the high nickel ternary system.

Therefore, the improvement of electrolyte formula can be rapidly iterated based on the accumulation of high nickel technology.

The use of deep simulation, high-throughput computing and other data-driven research

and development methods can accelerate the iteration of manganese iron lithium material system development.

For example, the manganese iron ratio and modification technology can be rapidly iterated and developed through material calculation and experimental simulation,

accelerating the commercialization process.

Battery factories with data-driven research and development platforms may have technological and cost advantages.

Process route: Liquid/solid phase methods have their own advantages and disadvantages, and are expected to show a parallel development trend

The preparation methods of lithium manganese iron phosphate are similar to those of lithium iron phosphate, mainly including solid-phase and liquid-phase methods.

Both routes have their own advantages and disadvantages, and the process route presents a parallel pattern.

Liquid phase method: The finished product has high quality, but the compaction density is low, and the process steps are relatively complex

The liquid-phase method is beneficial for mixing manganese and iron, resulting in high quality finished products.

The liquid-phase method is beneficial for controlling the proportion of elements and making the manganese iron more uniform,

resulting in better product consistency and crystallinity.

However, it has low compaction density, complex process steps, and certain environmental pressures, with a higher unit investment.