Dimensionality design of carbonaceous materials for high-performance lithium metal batteries

Aug,07,24

Background introduction

To develop the next generation of high-performance batteries,

metal lithium negative electrodes with ultra-high specific capacity (3860 mAh g-1)

and low redox potential (relative to standard hydrogen electrode (SHE): -3.04 V) have become a widely researched hotspot.

However, uncontrollable dendrite growth, low Coulombic efficiency,

and significant volume changes have seriously hindered the commercial application of lithium metal anodes.

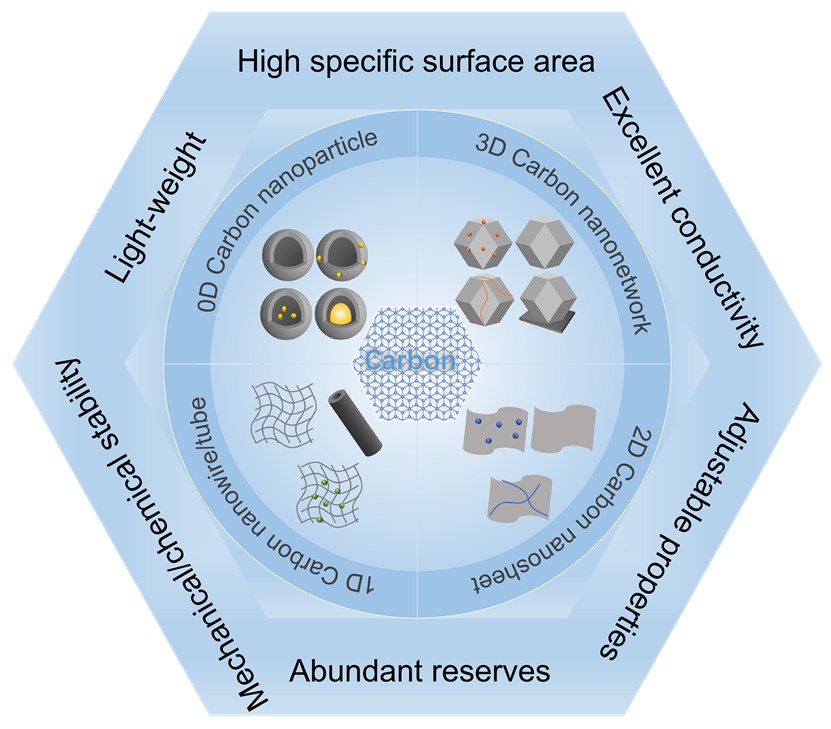

Carbonaceous materials are considered a very promising metal lithium host/carrier material due to their high electron mobility,

stable electrochemical properties, adjustable physicochemical properties, and lightweight characteristics.

Full text overview

This review first reviews the latest developments in carbon host/carrier regulation and design;

Based on the dimensional changes of carbonaceous material units, summarize and discuss the lithium affinity modification strategies of carbon hosts/carriers,

as well as the relationship between the dimensional changes of carbonaceous material units and the regulation of lithium affinity and electrochemical performance.

Finally, a development direction and prospect for the rational construction of high-performance carbon hosts/carriers for practical rechargeable lithium metal batteries are proposed.

Text and image analysis

Figure 1 Schematic diagram of constructing multi-level carbon hosts/carriers using carbon units of different dimensions

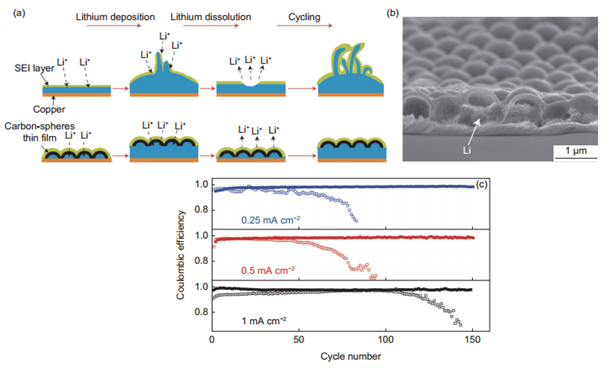

(1) 0D carbon balls have excellent chemical stability, good electronic conductivity, and low cost,

and have been widely used as conductive additives or ideal hosts/carriers for anchoring various electrochemically active positive electrode materials (such as S, Se, etc.) in lithium batteries.

0D carbon spheres have also been widely used in the design of carbon hosts/carriers for metallic lithium,

effectively suppressing issues such as lithium dendrite growth and significantly improving the electrochemical performance of metallic lithium anodes.

Figure 2 (a) Schematic diagram of Li deposition/stripping process on different substrates;

(b) SEM image of Li deposition;

(c) Cycle performance at different current densities

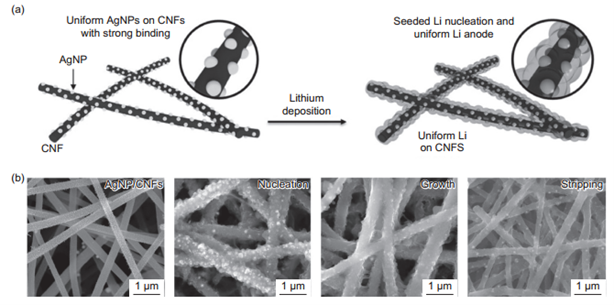

(2) 1D carbon materials are widely used in constructing 3D cross-linked carbon conductive networks to solve

the many challenges faced by metal lithium anodes due to their lightweight,

large specific surface area, and excellent flexibility. Carbon nanotubes (CNTs) and carbon fibers (CFs), as representatives of one-dimensional carbon nanomaterials,

have been widely reported in the construction of metal lithium hosts/carriers to suppress the growth and volume expansion of metal lithium dendrites.

Figure 3 (a) Schematic diagram of the uniform Li metal deposition process on a three-dimensional substrate modified with silver nano seeds;

(b) SEM images of AgNP/CNFs at different cycling stages

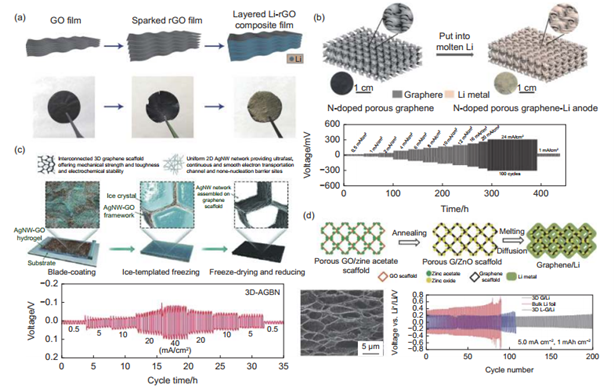

(3) Graphene is a carbonaceous material with sp ² hybridized carbon atoms tightly packed into a single-layer two-dimensional honeycomb lattice structure.

It is widely used to construct carbon hosts/carriers to suppress the growth of metallic lithium dendrites and significant volume changes,

and to obtain stable electrolyte contact interfaces.

Figure 4 (a) shows the preparation principle of sandwich shaped composite electrode film;

(b) Preparation process and rate performance of N-doped graphene lithium electrode;

(c) Preparation flowchart and rate performance of 3D-AGBN electrode;

(d) Preparation process, SEM images, and cycling performance of 3D G/Li electrodes.

(4) Due to its large specific surface area, low cost, easy synthesis, and adjustable microstructure,

3D carbon frameworks have been widely used as carbon hosts/carriers for metal lithium anodes and have received widespread attention.

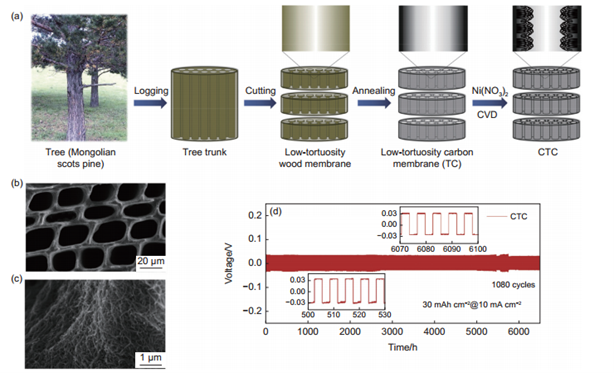

(a) CTC electrode preparation process; (b-c) SEM photos; (d) The cycling stability of CTC electrodes.

Subsequently, the review discussed the characteristics of constructing carbon hosts/carriers with different dimensions of carbon units:

0D carbon spheres typically require additional binders,

1D and 2D carbon nano units have great potential in designing three-dimensional self-supporting multi-level carbon hosts/carriers for metallic lithium,

while 3D carbon frameworks have advantages such as low cost and easy synthesis.

Finally, this review summarizes and looks forward to the following aspects.

(1) The air instability of metallic lithium requires storage/use in argon glove boxes or drying rooms,

therefore improving the environmental tolerance of metallic lithium electrodes is extremely important for reducing processing costs

and enhancing the safety of metallic lithium batteries.

(2) Although some research has constructed carbon hosts/carriers with efficient electron and lithium ion transport networks,

the design of high rate metallic lithium electrodes remains a significant challenge.

(3) Although many studies have reported the carbon host/carrier of flexible self-supporting lithium metal,

the interfacial electrochemical behavior during bending and folding processes needs further in-depth investigation.

(4) From a practical perspective, the deposition amount of metallic lithium in electrodes is an important indicator for evaluating practicality.

Therefore, the problem of metallic lithium overload in metallic lithium electrodes needs more attention.

(5) Although various carbon hosts/carriers have been reported and achieved significant results in the research of metal lithium anodes,

how to prepare these carbon units on a large scale and at low cost is still an urgent problem to be solved.