PRODUCT FEATURES

The first generation of commercial cathode materials for lithium-ion

batteries have many irreplaceable advantages: good processing performance, high

density, relatively high specific capacity, stable structure, good cycling

performance, high voltage platform and relatively stable. It is the most mature

and the only commercial cathode material at present, especially in the field of

communication batteries in a short time There are also irreplaceable

advantages。

The first generation of commercial cathode materials for lithium-ion

batteries have many irreplaceable advantages: good processing performance, high

density, relatively high specific capacity, stable structure, good cycling

performance, high voltage platform and relatively stable. It is the most mature

and the only commercial cathode material at present, especially in the field of

communication batteries in a short time There are also irreplaceable

advantages。Disadvantages: expensive, capacity almost to the limit, lack of resources,

poor security and other defects make it inevitable to be replaced in the last 5

to 10 years. At present, there are two directions to replace lithium cobalt

oxide. One is in the field of power battery, lithium manganate and lithium

ferrophosphate are the most promising materials. The other is in the field of

communication battery, nickel cobalt lithium and nickel cobalt manganese lithium

ternary materials are the most promising cathode materials to replace lithium

cobalt oxide. The liquid phase synthesis process of lithium ion two battery

positive electrode material (lithium cobalt oxide) is made by using polyvinyl

alcohol (PVA) or polyethylene glycol (PEG) aqueous solution as solvent, and

lithium and cobalt salts dissolved in PVA or PEG aqueous solution respectively.

After mixing, the solution is heated to form gel. The gel is then heated and

decomposed and then calcined at high temperature. The lithium cobalt oxide

powder is obtained by grinding and sieving the sintered powder. Compared with

the prior art, the invention has the advantages of low synthesis temperature,

high purity, uniform chemical composition, etc. The automatic f-sorb2400

specific surface area tester was used.

characteristic

1. Excellent electrochemical performance

a. The average capacity attenuation of each cycle is less than 0.05%

b. The first discharge capacity is more than 135mah / g

c. 3.6V initial discharge platform ratio > 85%

2. Excellent processability

3. The high tap density is helpful to improve the volume specific capacity

of the battery

4. The product has stable performance and good consistency

Product model

The tap density of r747 is 2.4-3.0g/cm3, the typical value is 2.5, and the

particle size is d506.0-8.5um;

The tap density of r757 is 2.4-3.2g/cm3, the typical value is 2.6, and the

particle size is d506.5-9.0um;

The tap density of r767 is 2.3-3.0g/cm3, the typical value is 2.5, and the

particle size is d508-12um;

technical standard

1. Title: LiCoO2 molecular formula: LiCoO2 molecular weight: 97.88

2. Main application: lithium ion battery

3. Appearance requirements: gray black powder, no caking

4. X-ray diffraction: compared with jcds standard (16-427), there was no

impurity

5. Package: packed in plastic bag in iron bucket

6. Chemical composition and physical property index:

Project items scope

Ni 0.05% max (wt%)

Mn 0.01% max (wt%)

Fe 0.02% max (wt%)

CA 0.03% max (wt%)

Sodium 0.01% max (wt%)

PH 9.5-11.5

Moisture content (105oC dry weight loss,%) moisture (wt% lossat105oc) <

0.05

Specific surface area (m2 / g) betsurfacearea (m2 / g) 0.2-0.6

Tap density (g / cm3) 1.7-2.9

Particle size-d50 (μ m) psd-d50 (μ m) 5-12

Particle size - D10 (μ m) psd-d10 (μ m) 1-5 particle size - D90 (μ m)

psd-d90 (μ m) 12-25

-

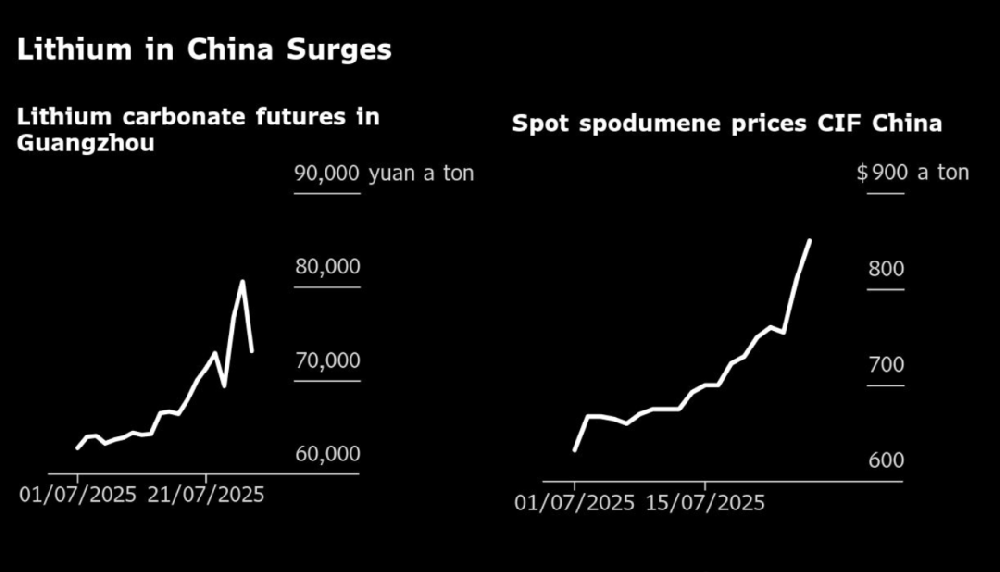

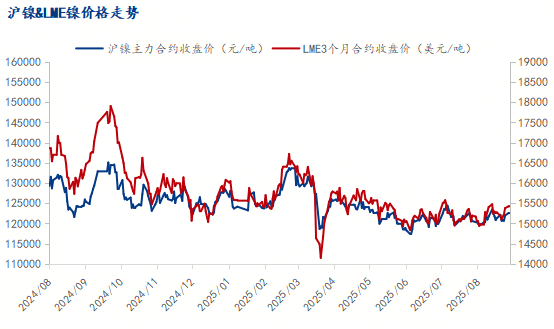

Nickel Market Update - October 28th

Oct,29,2025

-

Market Update on Nickel Prices in Nov.2025

Oct,29,2025

-

Oct,29,2025

-

Mid week analysis of cobalt lithium new energy market and prices in October 2025

Oct,29,2025